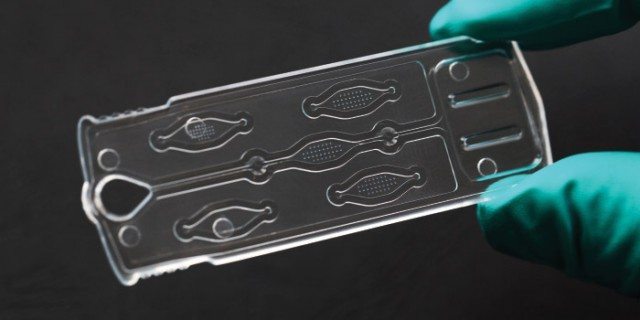

In collaboration with academia and industry, researchers at the Technical University of Denmark (DTU) Nanotech have developed a new portable lab-on-a-chip platform suitable for simultaneous detection of several pathogens at the point of need in food processing industries such as in slaughterhouses.

The portable SMARTDETECT provides all the functions of an analytical laboratory in a chip and can be employed directly on the production line to screen for harmful bacteria in food at considerably reduced time and cost.

Considering the pace of today’s food processing and global distribution network, a fast and accurate screening of food products is essential.

Rapid in-field detection of pathogens expedites the timely release of products for retail distribution and mitigates foodborne diseases and economic loss.

Combining nanotechnology and molecular biology

Two newly developed technologies are essential, to performing a fast and reliable screening of pathogens.

The first is a new molecular method called ‘Direct solid-phase polymerase chain reaction’. Polymerase chain reactions (PCR reactions) serve to amplify a piece of DNA to facilitate detection.

Unlike the conventional liquid-phase PCR, the new method makes it possible, to simultaneously perform dozens of different PCR reactions at several separate locations on a solid substrate with minimized interference.

In this way, the new ‘Direct solid-phase PCR reaction’ allows DNA of several different bacteria or subspecies to be amplified at the same time.

“We use a special inhibitor-resistant enzyme and because of this enzyme, the raw samples can be handled directly,” says associate professor, Yi Sun.

“We do not need the tedious sample preparation procedures.”

This development has been performed in collaboration with DTU Food.

During the solid-phase PCR, fluorescence signals are generated from each of the different PCR reactions.

To efficiently detect all these signals and thereby identify the presence of pathogens, the second technology, an optical detection method based on a concept called ‘Super Critical Angle Fluorescence’ (SAF), is brought into play.

This technology is highly sensitive and it is multiplexed, enabling simultaneous detection of optical signals from multiple points.

Using an advanced microfabrication technique, researchers at DTU Nanotech have incorporated a cone-shaped SAF micro-optic array into a polymeric microchip.

By collecting light at a super critical angle, that is the direction to which the majority of fluorescence light emits, the SAF structure works as a high-quality lens, dramatically increasing the sensitivity by nearly 50 times.

Genomic DNA

Genomic DNA

If pathogens are present in the sample, their DNA will be captured by the specific DNA probes immobilized on the surface of the SAF array.

During solid-phase PCR, millions of copies of pathogen DNA will be generated, and the PCR products will be labeled with fluorescent dye (the yellow ‘stars’) and detected through the SAF array.

30 targets detected simultaneously

While the two technologies have demonstrated prestigious characteristics on their own, combining the two in an integrated system results in even higher impacts.

Researchers at DTU Nanotech and DTU Food have succeeded in performing direct solid-phase PCR on the surface of the cone-shaped SAF array embedded in a microfluidic chamber.

They showed that ultra-sensitive, rapid (0.5-1 hours instead of two days) and multiplexed (30 targets) pathogen detection could be achieved on a low-cost and portable microfluidic system.

Associate professor Anders Wolff says that “the chip-based portable laboratory completely eliminates the need for transport of samples to a central laboratory and we believe it will fundamentally change the paradigm for microbiological diagnostics and set new standards for the detection of harmful bacteria in food production.”

Story by Pernille Broen Larsen from DTU