High food waste levels remain a serious problem in cities today, placing a strain on global resources and government expenses.

Up to a third of all food is spoilt or squandered before it is consumed, costing the world almost US$1 trillion each year.

In response, more businesses are pledging their commitment to sustainable development and improving efficiencies, turning the spotlight on high-tech food preservation methods that place more products with improved shelf life, freshness and nutritive value in retail stores and on dining tables.

These solutions are helping manufacturers and households cut back on waste, allowing foods to be exported further, and expanding food options for consumers.

The list of novel technologies designed to reduce spoilage while retaining product color, flavor, texture and nutrient content continues to grow – these run the gamut from blue light-emitting diode or LED and cold plasma to high pressure processing and pulsed electric fields for heat-sensitive foods.

The importance of food grade gases in many of these applications is often overlooked.

Among them is nitrogen, a colorless, odorless, non-toxic and inert element that serves as a processing aid and additive.

A versatile component, nitrogen is mainly used in modified atmosphere packaging, and in processes such as coffee packaging and the fluffing of cream and desserts.

The growing demand for fresh and quality products are already driving advancements in processing and packaging technologies, introducing new food preservation techniques that leverage nitrogen’s unique properties in both compressed air and liquid forms.

Quality with quick freezing

While usually associated with convenience, frozen food offers benefits beyond its quick and easy preparation.

Frozen products not only lock in the nutrients and vitamins that fresh foods often lose during transportation, but they also contribute to less waste as they can last for weeks or even longer.

With food companies increasingly targeting health-conscious, on-the-go consumers, improved freezing technologies have been crucial to developing healthier, simpler and more flavorful frozen ingredients and meals.

Meanwhile, cryogenic technology – cold processing using carbon dioxide or nitrogen – has made significant advances in recent years.

The process involves injecting liquid cryogen into the freezer to remove heat from foods within minutes.

Ultra-fast freezing means that smaller ice crystals are formed, causing less damage to the food’s cellular structure. Products are thus able to better retain moisture, texture and flavor.

Early this year, Linde introduced its latest cryogenic freezer that combines wave-impingement technology and the physical motion of products to boost yield and improve product weight.

Equipped with a conveyor belt that features a patented rolling-wave action, the machine promotes more even freezing and less sticking.

As individual items are gently tossed, they are hit with a high-velocity convective flow of liquid nitrogen.

Apart from protecting the shape and quality of the food product, the freezing technology ensures reduced dehydration losses and improved shelf life.

The freezer is ideal for processing meat, poultry, seafood and items like meatballs, sausages and pizza toppings.

Frozen food has stayed largely resilient amidst evolving food trends, appealing with its longer nutritional lifespan, convenience and lower cost.

With frozen food industry expected to reach US$363.9 billion by 2024, continuous improvements to freezing technologies become even more important.

Purity in beverage processing

Similarly, nitrogen plays an essential role in beverage manufacturing, in processes like sparging and inerting.

It helps prevent the discoloration and off-flavors of non-carbonated drinks like wine, iced tea, fruit juices or milk-type beverages by effectively removing dissolved oxygen in the liquids.

Nitrogen also provides internal pressure and rigidity to stabilize thin-walled receptacles like polyethylene Terephthalate or PET bottles.

For facilities that require continuous nitrogen flow, from processing right up to the filling stage, reliable onsite nitrogen generation is critical.

BOGE’s scroll compressor technology, through its Eccentric-Oilfree series, is designed for such sensitive applications.

Here, aluminum spirals in the compressor chamber intermesh but do not touch, generating pulsation- and oil-free compressed air for beverage manufacturing.

Once connected to a nitrogen pressure swing adsorption (PSA) generator, the compressors efficiently supply pure compressed air that is particularly useful in decanting wine.

Nitrogen, in this case, prevents further wine fermentation and the formation of bacteria and mold in the bottle.

The elimination of contaminants ensures that the quality of the wine is maintained over a long ageing process.

Offering efficient energy use and less wastage, users can adjust the power delivery and quantity of their compressed air using the nitrogen PSA generator.

Obtaining a ready supply of nitrogen can be challenging and expensive, thus making cost-efficient compressed air systems an asset in the manufacturing process.

Smart packaging freshness

The rise in demand for natural, preservative-free foods that stay fresh for longer has also encouraged manufacturers to turn to innovative packaging solutions that can slow down oxidation, inhibiting microbial growth and removing excess moisture that can expedite food spoilage.

Such packaging technologies have been extremely useful for chopped fruits and vegetables as they turn brown quickly due to oxidation. Using packaging filled with a mixture of gases can delay browning and increase the shelf life of fresh fruits by up to 10 days.

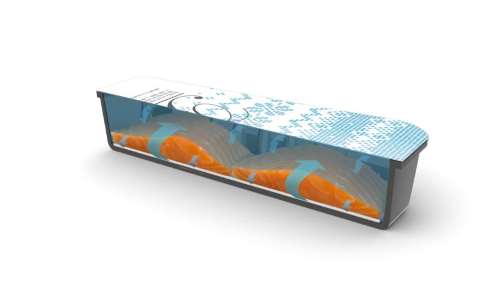

In modified atmosphere packaging (MAP), the rate of oxidation is controlled or decreased – this is achieved by displacing oxygen in the pack with nitrogen and carbon dioxide (CO2).

The protective atmosphere preserves freshness, flavors and texture, resulting in shelf-stable products that maintain their attractive appearance for longer.

Nitrogen simultaneously serves to neutralize carbon dioxide’s absorption effect to ensure that packages hold their shape and keep fragile food products intact during storage and transport.

In efforts to bring quality, longer-lasting foods to consumers, Cellcomb and Vartdal Plast developed the SuperFresh CO2 pad, an absorber that enhances the function of MAP.

The pad can be easily placed into packages to activate a reaction that releases carbon dioxide.

Product deterioration is slowed down even more to extend freshness and ultimately, lessen food waste.

To date, the pad has successfully increased the shelf life of fresh fish and poultry by 30-40%.

Pads designed specifically for skin pack are also available and function by releasing the right amount of CO2 dioxide without disrupting the vacuum of the packaging.

MAP and other related innovations have since been applied widely – in packing prepared salads, chilled ready-to-eat meals, dairy produce or snacks like nuts and potato crisps.

Feeding populations, minimizing waste

Concerted efforts to combat food waste generation are necessary if we are to feed growing populations and increase global food security.

The shift towards sustainability is driving innovations and new technologies that make use of existing resources – as simple as food grade nitrogen – to produce quality, nutritious foods that offer consumers great taste, improved choices and value for money.

For food companies, the increased adoption of new food preservation techniques introduces a whole host of benefits, including improved productivity and energy efficiency across the supply chain, possibilities for wider distribution and higher profits.

Story by Nalin Amunugama, GM, BOGE Kompressoren Asia Pacific