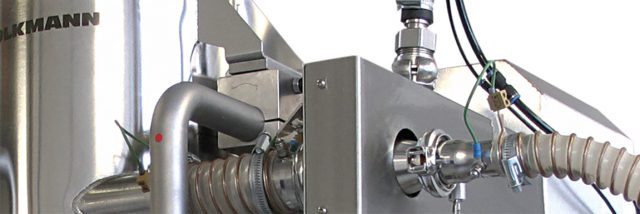

Volkmann displayed its vacuum conveying systems for transporting fine food powders, chemicals, granules, pellets, tablets and other small components in lean, dense or plug flow conditions along with its new products for contained product transfer at PackEXPO in Chicago, US last month.

Volkmann units provide a closed system with dust free feeds to protect employees and the work environment and meet ATEX certification standards for explosion protection.

The company’s weighing and dosing systems can for example accurately weigh and dose powders, granules, food particles, pellets, capsules, tablets and other bulk materials being transferred into and out of product pick-up, through vacuum conveying and into the final unit.

It has also upgraded and increased its line of bag dump (Rip and Tip) stations to include a variety of high containment models from a secure, glove box dump station with three discharge options (fluidizing with air or N2, mechanical agitator, pneumatic agitator) to OEB5 with push-push filter and Hepa filter options.

They also have upgraded their bulk bag unloading frame.

Meanwhile, Volkmann’s new mobile trolley unit allows the positioning of Volkmann receivers anywhere on the production floor.

The unit comes with programmable height adjustment that eliminates hoisting being limited to the dimensions of a rod-less or pneumatic cylinder while also overcoming the tendency for cylinders to ‘sag’ with time.

Story by Sharon Marshall