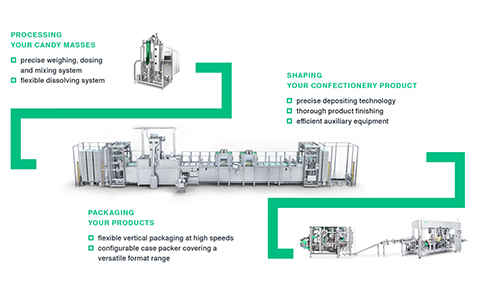

The dynamics of the confectionery industry are nowhere more apparent than in the jelly sector.

There seems to be no limit to colors and shapes, and manufacturers are constantly developing new, colorful creations.

Jellies enriched with vitamins and nutritional supplements for children and adults are among the ongoing trends.

For producers who want to prevail over competition, this fast-moving market environment triggers the need for efficient and flexible process technology.

Dietary supplements in jelly

The increasing demand for so-called “nutraceuticals”, dietary supplements enriched with vitamins or other additives, in jelly form is a sought-after trend in the confectionery industry and is partly responsible for the dynamic market developments.

These vitamin bears or collagen drops are often produced in simple, uniform shapes, which makes them suitable for another trend in confectionery production: starchless depositing.

The starchless depositing process enables jelly producers to manufacture a final product that complies with the guidelines for dietary supplements and over the counter) products.

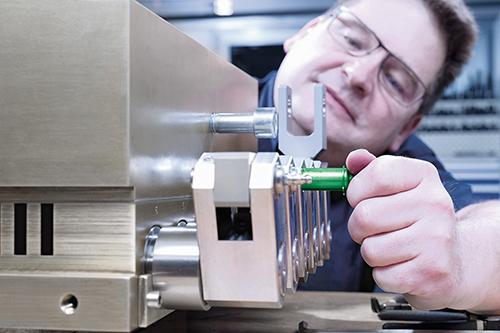

“Starchless depositing eliminates the need for starch. Instead, the jelly mass is poured into special reusable molds,” Dr. Sandra Link, product manager at Makat Candy Technology, explains.

“We have optimized our equipment in order to ensure a high-quality depositing process of masses with a high dry substance content.”

After depositing, the product molds with the jelly mass pass through an integrated cooling tunnel and are brought to the required demolding temperature.

Once the jellies have been demolded, the empty molds return to the depositor and the process starts all over again.

“In the traditional starch-based depositing process, the starch trays have to remain in a curing room for up to 72 hours depending on the formulation,” she says.

“The starchless depositing process has several advantages. It reduces production time and the products no longer have to leave the machine for cooling.”

“In addition, jelly producers save the space and energy costs for the curing rooms, as well as all expenses for starch handling and conditioning – which also eliminates expenses for ATEX protection.”

Digitalization, remote work

When travel restrictions reduce personal contact to a minimum, other means of communication are required to make sure that time-critical projects do not come to a standstill.

Even during a global pandemic, new lines need to be commissioned and existing machines need maintenance, which requires remote services and support solutions for this season.

For example, customers usually come to the manufacturer’s plant for an FAT (Factory Acceptance Test).

During Covid-19 restrictions, however, this is not always possible.

Together with their customers, Makat took the opportunity to transfer the FAT of a new machine to the virtual level: The complete process of commissioning was filmed by a webcam.

This way the service experts always had an optimal overview of what was going on and could advise the technicians on site in real-time.

In general, the pandemic increased the level of digitalization, which Makat offers remote services for customers, but also ensures new machines are ideally suited for the use of Industry 4.0 solutions.

Besides that, the global pandemic forced companies to devote even more attention to product safety and germ reduction.

Despite the highest hygienic precautions, manual processes are increasingly seen as a potential risk in food production.

Manufacturers of jellies and other confectionery products are therefore progressively automating their cleaning and sanitizing processes in order to seamlessly protect consumers and guarantee product safety.

Story by Laura Kossmann, Sales & Marketing, Makat Candy Technology GmbH, a Syntegon company