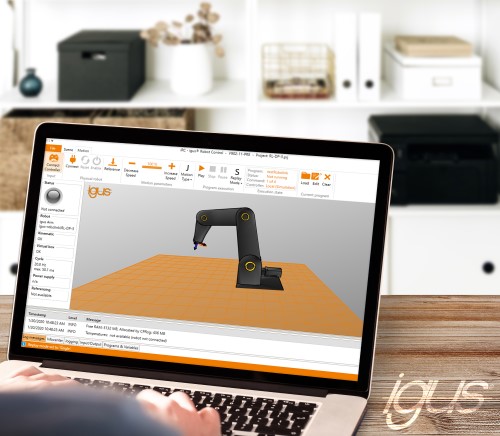

Igus is offering a free and license-free software for the simulation and programming of all its robots to enable users to try out in advance which robot is best suited for their application.

In the software there is a digital twin for all igus robots, which can be simulated and taught like the real robot.

The robot control system is also used later to program the robot intuitively.

Every programming can be applied to the real robot afterwards.

The complete hardware package, for example, the company’s drylin linear robot with integrated control system in the switch cabinet, is available from €5,000 (US$5,896.08).

Easy programming of robots

With igus robot control, the user can freely move all axes of the digital twin via a 3D interface.

Using a teach-in function, the robot can be programmed very easily, even without a robot connection.

To do this, the user must manually move the robot to the desired position and define how it is to be moved.

The process is repeated until the desired motion profile is created.

Matching end effectors, such as grippers, are easy to add and the tool centre point adjusts automatically.

Virtual boxes can also be installed, for example, to prevent the robot from colliding with a machine.

The igus robot control can also be connected to a higher-level control system, either via interface communication with Digital IO or via Ethernet communication using IP address.

“In the future, we want to offer cloud services such as vision integration, remote commissioning and also online training for a small cost, which the customer can book,” says Alexander Mühlens, head of automation technology.

“Further services such as image evaluation via webcam or bin picking solutions are planned as cloud-based solutions.”