tna has launched a new turnkey vibratory motion blending system to accurately mix multiple dry or wet products.

The tna roflo VMBS 3 combines speed, continuous vertical motion and mass flow technology to deliver blend accuracy, recipe control and reduced ingredient costs.

Suitable for both dry and wet environments, the machine can blend products including baked and fried snacks, nuts and dried fruits, pet food, pasta, cereals and gummies.

It can also mix fresh and frozen products like salads or frozen vegetables.

Incorporating tna’s weighing technology with an integrated load cell, the tna roflo VMBS 3 measures each ingredient accurately, delivering maximum system precision and control over both recipe and costs.

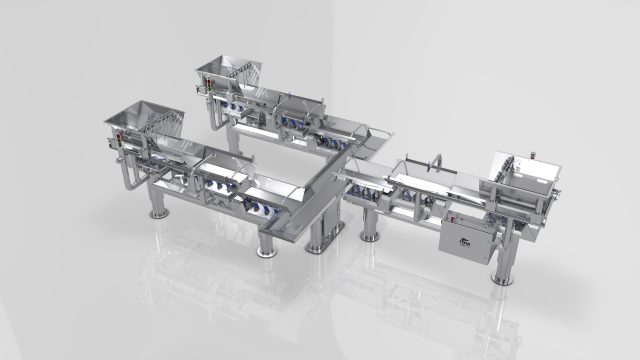

Each integrated ingredient input module (IIM) of the machine has a highly compact design, comprising an infeed conveyor with hopper, control conveyor and weigh conveyor.

Depending on recipe requirements, manufacturers can combine up to 22 IIM modules, all of which are centrally controlled by a single controls system.

The system’s hygienic, washdown design with a stainless-steel construction, no wearing parts and a mobile hopper facilitates cleaning, reduces maintenance and ensures superior equipment reliability.

In addition, the machine operates on natural frequency, requiring minimal amount of energy for a more sustainable production process.

The tna roflo VMBS 3 is suitable for a variety of infeed methods, including manual or bulk or directly connected to the processing line.

Output can be fed onto a variety of distribution systems, including tna roflo vibratory, horizontal or belt conveyors.