‘Retro’ is not always the right way to go.

While retro design continues to be a trend for cars, clothes and furniture, it is a different story when it comes to food, says SIG Combibloc.

Consumers love a fresh look, and this applies for preserved products as well.

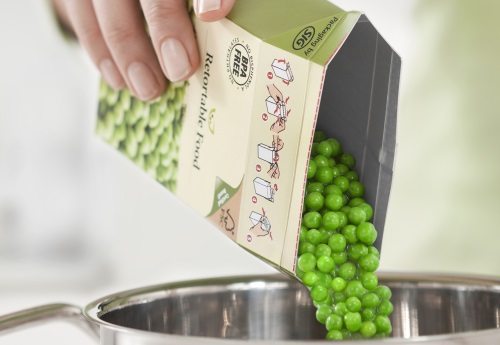

So more of the products typically sold in food metal cans or glass jars are now being brought out in carton packs instead.

More than 200 products are now on sale in combisafe, the heat-resistant carton pack from SIG Combibloc.

It fills long-life food products with a very high particulate content, such as vegetables and pulses, fruit, ready-meals and stews.

The heat-resistant carton packaging can be filled with practically any chunky food product and subsequently sterilized in an autoclave.

The company says many stores already offer traditional canned products in combisafe.

“For retailers choosing a packaging solution, in addition to providing protection for a top-quality product, considerations such as logistical efficiency and advertising effectiveness on the sales shelf are more important today than ever before,” says Ralf Mosbacher, head of food Europe.

Transportation, shelf sales

Like all SIG Combibloc carton packs, combisafe carton packs are transported to the food manufacturer’s production plants as flat folded sleeves, thereby making the most efficient use is made of a truck’s loading volume.

Once the carton packs have been filled with the product, a truck en route to distributors is transporting about 95% content, and 5% packaging.

With truck transportation, carton packs also score over other packaging solutions as they are light weight, compact, rectangular and unbreakable.

Carton packs stack well and use the full capacity of pallets, and therefore also of trucks and warehouses.

“Compared to glass packaging for food products, for instance, up to 93% packaging weight can be saved with carton packs. Every saving on space and weight means fewer emissions, reduced consumption of fossil resources, and lower costs,” says Mosbacher.

“And on the sales shelf too, the available space can be utilized most efficiently. With their right-angled shape, carton packs fill up the available space about 30% better than metal cans”.

Eye-catchers, brand ambassadors

On the canned foods shelf, combisafe offers a natural, fresh look with freedom of design due to their four printable sides.

For the consumers, combisafe is lightweight, unbreakable and easy to use.

The perforation right across the carton top means users can open combisafe easily without scissors or knives, and empty the carton pack completely, thereby offering convenience.

Environmental performance

Like all other SIG Combibloc carton packs, combisafe is made mainly from wood, a renewable resource.

If the wood originates from responsibly managed forests, this natural raw material is available in a virtually infinite supply.

As wood is carbon-neutral, it does not alter the CO2 balance in the atmosphere.

“We make sure the cardboard we process is manufactured exclusively using wood pulp originating from controlled and responsibly managed sources,” says Mosbacher.

“That makes carton packs unique in the packaging mix for long-life foods, and is reflected in a positive impact on the environmental performance of our customers’ products and production processes.”

“A recent life-cycle assessment has confirmed that, compared to other long-life food packaging solutions, carton packs can cut CO2 emissions by more than 60% and fossil resource consumption by even up to 69%.”

“The study compared food metal cans, glass jars, carton packs, plastic pots and plastic pouches”.

Rotary autoclaves, multi-head scales

When filling food products in combisafe, the sleeve system and the volume-flexible filling machine technology of SIG Combibloc are used.

First, the carton packs are shaped on the filling machine and sealed across the base.

The food is then filled into the carton packs, in several stages if necessary.

Products can be filled using three modular filling units, including a high-precision multi-head weigher.

The size and quantity of the chunky product ingredients can vary in virtually any respect, and they can be measured out precisely.

In a first stage, pumpable products are filled; chunky product ingredients follow in a second stage, and in a third stage the liquid is added.

After the carton top has been ultrasonically sealed, product and packaging are sterilized in an autoclave.

The composite structure of combisafe is designed to permit the heat treatment of product and packaging in the autoclave.

Along with the cardboard, there is a layer of aluminum (protection from light, external odors and oxygen), and polymer layers (liquid barriers and heat protection).

“Not only do the autoclaves guarantee that superior product quality is retained, they also make it possible, through the continuous movement of the carton packs while they are undergoing the effects of heating, to fill and process certain products in the first place,” says Mosbacher.

“This applies, for example, with viscous foods containing extra-large particulates, such as the popular baked beans and chunky products.”

Applications include assorted vegetables in sauce packaged in ready-meals, tomato products, soups and pasta sauces, as well as organic vegetable mixes that have typically been sold in food metal cans or glass containers.

The company says fruit is another candidate for safe, long-life packaging in combisafe, and can be stored without refrigeration or preservatives for up to two years, with no loss of quality.

With combisafe, the SIG Combibloc filling machine system can fill 200, 300, 400 and 500 ml at one time.

A volume switch takes a few minutes – and the carton design can be changed without interrupting the production process.