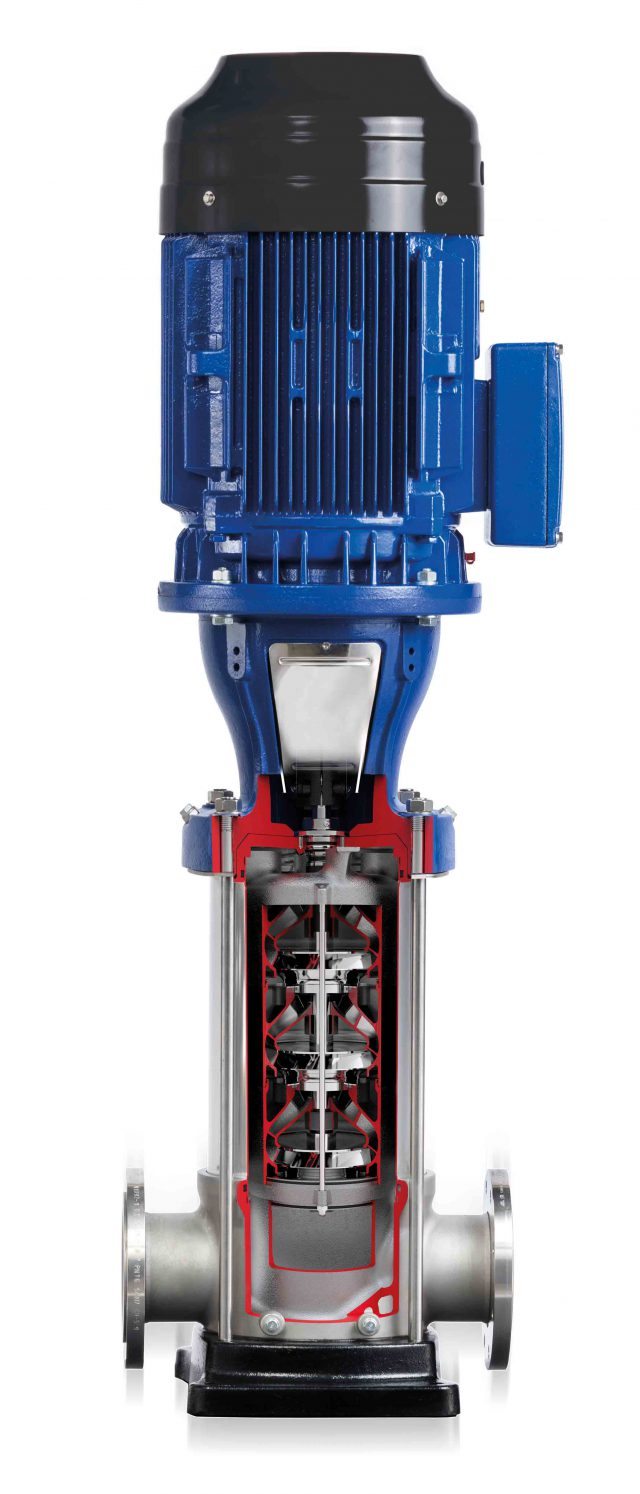

KSB is launching its Movitec 125 pumps, complementing its current range of vertical high-pressure pumps.

The multistage centrifugal pumps are designed for fluids such as water, coolants, condensate and mineral oils.

They are ideal for industrial recirculation and fire-fighting systems, cooling water circuits and washing plants as well as for boosting pressure in general process applications.

The efficiency of a pump with a full impeller diameter is greater than 80%.

The type series handles flow rates of up to 192 m3 per hour (at 60 Hz) at heads of up to 125 m.

The permissible fluid temperature ranges from -20 °C to +120 °C.

As standard, the new pump sets are driven by 2-pole IP3 motors of 15 to 45 kW.

The pumps are fitted with product-lubricated plain bearings made of tungsten carbide, cast bases, and torsion-resistant pressure shrouds sealed by confined O-rings.

Corrosion-resistant hydraulic components made of stainless steel further add to these qualities.

In addition, they have material variants and flange connection options for installing and operating the new pump sets, as well as easy-to-replace standardized cartridge mechanical seals to EN 12756.

As an option, the pump can be operated on a frequency inverter and combined with high-efficiency motors to increase the system’s efficiency and match the flow rate to actual demand.