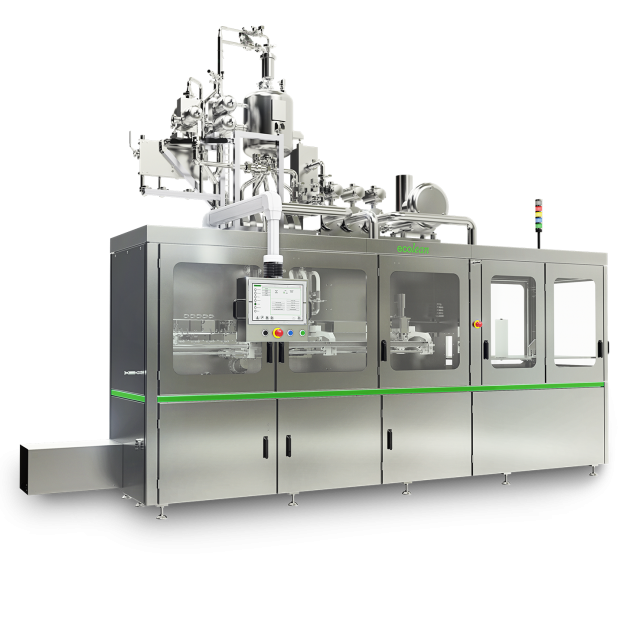

Ecolean announces the EL2+, an upgraded filling machine for chilled distribution portion-sized packages.

The compact filling machine has five fillers and a redesigned servo system that uses motors instead of pneumatic cylinders so as to double capacity by reducing cycle times nearly 40% – from 2.4 seconds to 1.5 seconds.

Portion-sized packages are produced up to 12 000 packages per hour.

“The EL2+ now uses the latest Omron control system that features a virtual master servo axis to enable optimization of machine performance,” says Christian Olsson, director filling line operations.

“The technology was previously only used on our ambient filling machines, but the proven control system design is now available for the chilled segment with the EL2+.”

The infeed has a mechanical cam system and servo motors that control the opening of the packages as well as package grippers, all by one cam movement.

This increases reliability, durability and requires less overall machine maintenance.

In addition, the EL2+ increases product safety and quality with a fully-automated cleaning system of the filling zone that ensures the same level of hygiene at the start of every production cycle.

A steam system can be added to the valve cluster system made with aseptic membrane valves, which enables sterilization of the entire filling system before each production.

Other options for the EL2+ include a straw applicator for several different straw types, for easy on-the- go consumption.

The machine will be available in the third quarter 2017.