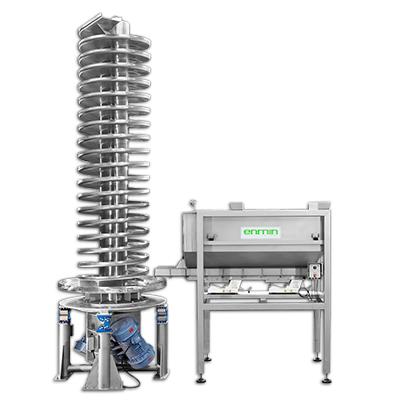

Enmin offers a new elevating spiral conveyor in Australia for conveying products and raw materials vertically to higher levels or conversely, down to near ground level.

It has a comparably small foot print, an ease of cleaning and almost maintenance-free operation for food production.

The solution uses the powerful acceleration of vibratory and a specially engineered spiral flight path to overcome the limitations associated with conveying material up an incline.

The result is the positive movement of material within the spiral, taking product from the in-feed point to the elevated discharge.

The profile of the spiral ensures no spillage during the transportation process and the totally sealed welding procedure prevents raw materials from accumulating in the spiral.

The open design also permits easy visual inspection and cleaning when changing ingredients and product.

The conveyor has no crushing points or exposed rotating parts, offering safe conveying whilst keeping noise to a low level.

With all contact surfaces constructed from stainless steel, the conveyor can handle a wide range of tonnages and a large array of dry materials and products.

Elevations of up to 7 m are available and the compact vibratory drive arrangement can be either base or overhead mounted.