Imagine a completely natural, abundant and easily renewable material that could feasibly be used to make lightweight car and aeroplane parts, strengthen building materials, form biocompatible tissue scaffolds, blood vessel grafts and medical implants, or make high-tech electronics and packaging material that keeps food fresh for longer.

The properties and qualities required to fulfil all these applications are found in the nanosized building blocks of cellulose, nature’s most ubiquitous structural molecule.

Cellulose nanofibers and nanocrystals extracted from natural sources as diverse as wood pulp (which is about 50% cellulose by weight percentage), pineapple leaves, grape skins and even some bacteria, are promising to provide us with an inherently safe, and ultimately ‘green’ resource that could revolutionize materials and biomaterials sciences.

A planet-full of cellulose

Humans have for millennia exploited the world’s abundance of cellulose-based materials, including wood, cotton, sisal, hemp and other crops, for our construction, textile, paper and food industries.

However, it wasn’t until 1977 that researchers first used homogenization to physically shear wood pulp cellulose fibres into their constituent nanofibrils, without destroying the glucose polymers.

Since then, scientists have developed mechanical, chemical and bioenzymatic methods to tease out the long, thin, cellulose nanofibrils (CNF) and shorter, more rod-like cellulose nanocrystal (CNC) structures from a huge range of plant and other biological starting materials.

Developing industrial-scale production processes

Ongoing nanocellulose research has shown that this globally available macromolecule could provide cheap, biodegradeable alternatives to petrochemicals-based materials, composites and mined metals.

This promise has spurred governments, industry and academia to step up nanocellulose research and development (R&D), and establish both small-scale and more recently, industrial-scale nanocellulose production facilities.

The Research Institutes of Sweden (RISE), for example, says that Sweden aims to have in place a platform for demonstrating the large-scale, sustainable manufacture of nanocellulose and nanocellulose-based high performance materials and products, from its own forestry resources, by 2025.

Applications of nanocellulose

Limitless potential

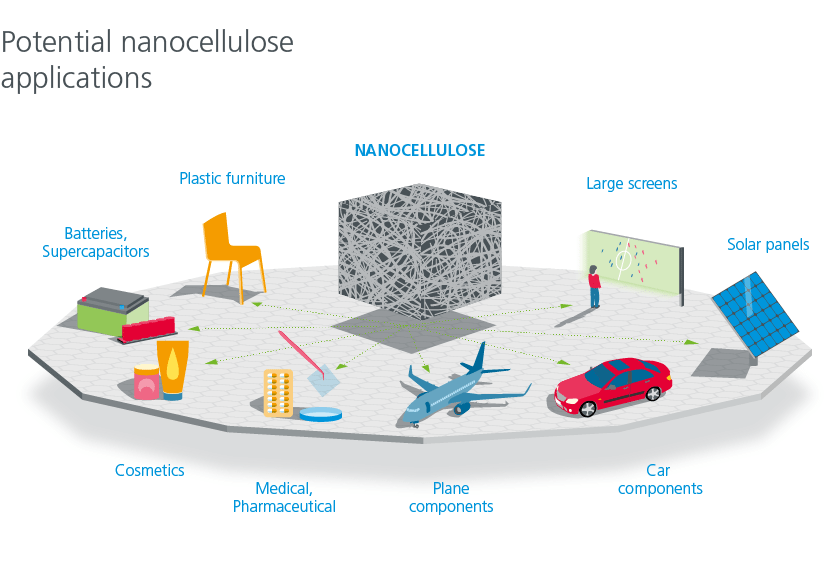

The potential applications of nanostructured cellulose are almost limitless.

Lightweight but stiffer than Kevlar and with eight times the tensile strength of steel, cellulose at the nanoscale can be electrically conductive, highly absorbent, and thermostable.

The material can be formed into sheets and other structures including laminates or transparent films, and incorporated into many different high performance materials for consumer, industrial and biomedical applications.

From paper to supercapacitors

As well adding strength to paper and paperboard, concrete and plastics, the properties of nanocellulose are being harnessed to improve the qualities of foams and gels, textiles and adhesives.

Nanocellulose composites might be developed as strong, lightweight, and cheap alternatives to non-renewable carbon fibre and fibreglass, and offer a sustainable alternative to the fossil-based plastics that are currently used to make products as diverse as plastic chairs and dustbins, and components for cars and aeroplanes.

CNC could be exploited for the manufacture of large screens and solar panels, or even to produce batteries and supercapacitors, or smart materials that respond to external stimuli such as heat, light, electricity, pH or pressure.

Nanocellulose could also form the basis of completely new pharmaceutical drug delivery materials, biosensors, diagnostics and even cosmetics.

And because nanocellulose can be derived from any plant source, including agricultural waste such as wheat straw, we may one day be writing on paper that has been produced without using any trees, or even water.

In parallel with continuing R&D focused on the end product applications of nanocellulose, industry is also developing sustainable, cost-effective and efficient technologies for producing the nanocellulose starting materials for industrial and medical applications.

The ultimate goal is to develop sustainable and environmentally sound industrial-scale production methods that minimize the use of energy and resources, and reduce waste.

Bottom up or top down

Nanocellulose can be produced using either bottom up methods, by constructing cellulose polymers from glucose monomer units, or by top down methods, which break up the plant cell walls and fibers to release the cellulose micro- and nanofibrils and nanocrystals.

The primary top-down nanocellulose production processes include acid hydrolysis for generating CNC, and high pressure (HP) homogenization for producing CNF, although new processes are also being reported.

Homogenization for nanofiber extraction

HP homogenization applies mechanical shear forces to break cellulose fibers down into their constituent nanofibers.

The shearing action destroys the plant cell wall matrix, releases the bundles of cellulose microfibrils, and then breaks the hydrogen bonds holding the nanofibrils together longitudinally, so that the long nanofibers are liberated.

The process can be aided by pretreatment using light grinding, enzymes, or chemicals that raise the pH.

Although CNF is primarily extracted from wood pulp, a wide range of other plant sources have been used, from flax and hemp, to carrots, potato, bamboo, coconut husks and sugar cane.

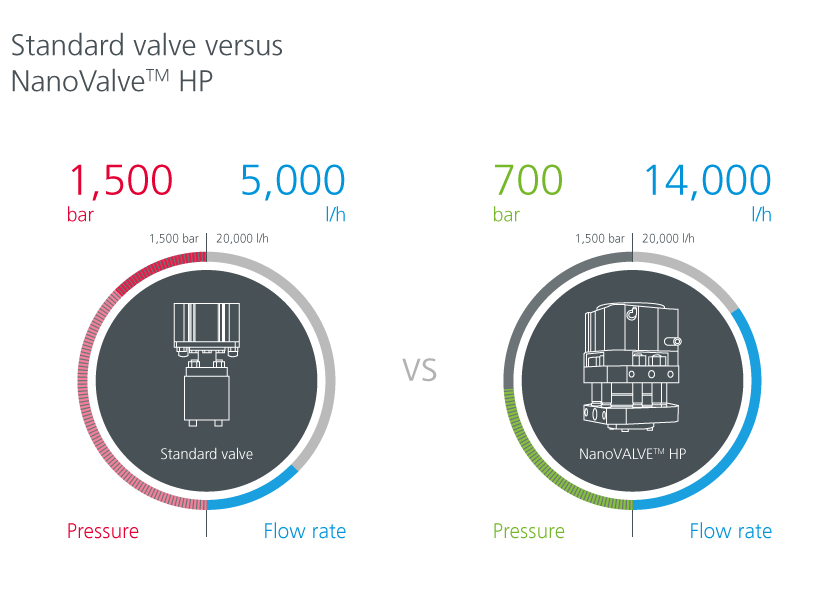

Standard versus NanoValve HP

GEA’s patented CNF homogenization valve, the NanoVALVE HP, enables faster processing of higher quality CNF, at much lower pressures and with reduced energy costs.

Standard valves process CNF from plant sources at a pressure of 1,500 bar, and typically enable a flow rate of around 5,000 l/h.

In comparison, the NanoVALVE HP works at half this pressure – 700 bar – but enables a flow rate of 14,000 l/h.

And because the system operates at lower pressure there is less heating of the nanocellulose as it is processed, and this reduces the need to cool the CNF emerging from the homogenizer.