Coveris has invested in a new converter machinery to increase manufacturing capacity of reclose-style labelling in its UK flexibles division.

In response to increasing demand and the growing trend of packaging recloseability, Coveris is now set to double production capabilities of reclose labelling at its Gainsborough site with this investment.

Reclose labelling is a label-film hybrid with an integrated aperture window, allowing packaging to be resealed once opened.

The reclose labelling offers improved ease of use and convenient in-pack storage.

Utilizing barrier technology through material and adhesive selection, reclose can extend open-pack product life, slow food discoloration and maintain freshness for longer, helping to reduce food waste in the home.

Offering flexibility, existing packaging designs and materials can be adapted and developed to incorporate reclose label technology line-by-line or across an entire range.

This allows brands and retailers to apply a reclose function to specific packs or pack sizes, whilst maintaining brand integrity and a consistent on-shelf appearance.

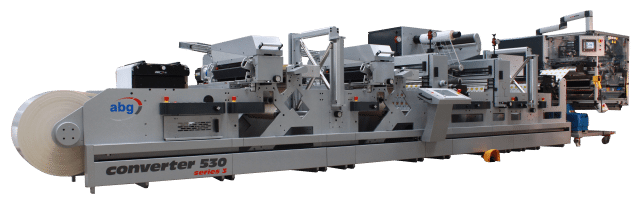

Installation of the machine, a Converter 530, Series 3 from ABG International, and production ramp up is currently underway at Coveris’ Gainsborough site.

Features on the converter include 100% camera inspection for superior quality, high precision Kocher & Beck Gap Master tooling and bespoke die-cutting settings.

Coveris’ UK Food & Consumer flexibles division has benefitted from further investment in production capabilities over the past year having installed two high specification Windmöeller & Höelscher Miraflex 8-colour presses, including one at its Gainsborough site.

More recently a new slitter with punch capabilities was added to the finishing portfolio at the Gainsborough factory in a bid to meet high seasonal demand at peak periods.