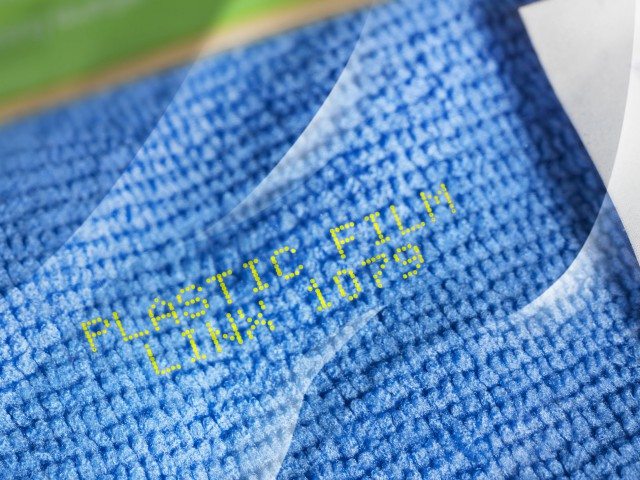

Linx Printing Technologies new opaque yellow pigmented ink is designed to deliver contrast on both light and dark substrates to ensure effective code visibility across a wide range of packaging applications.

The new Linx Yellow pigmented ink 1079 provides a fast drying time of within two seconds, allowing it to be used on fast-moving production lines or where products are handled soon after printing.

The ink can be used with Linx’s Midi plus and Ultima plus printheads on the company’s Linx 5900 and Linx 7900 series printers to code a wide variety of materials including plastics, in particular polyvinyl chloride (PVC), polypropylene, oriented polypropylene and PVC jacketed wire and cables, dry glass, card, and steel.

For industrial environments, it provides broad chemical splash and rub resistance, as well as excellent resistance to alkali, acid, water, alcohol, petrol and cutting fluid.

Linx 1079 also offers superior lightfastness, making it particularly suitable for products and packs that are exposed to light for extended periods.

The ink has a nine-month shelf life and printers can operate for up to 1,400 hours between scheduled maintenance.