Sidel is contracted to provide Blue Waters Products a complete line to bottle still water at its Trinidad plant.

The new line will allow the Caribbean bottler to boost production by an anticipated 40%, as well as minimize total cost of ownership (TCO) and increase sustainability.

This is the second installation with Sidel after one in its Orange Grove facility in Trinidad, where purified artesian water is bottled for distribution throughout the Caribbean early this year.

By increasing operating capacity, Blue Waters Products aims to better serve existing customers, improve cost efficiencies, add new products, and enter additional markets.

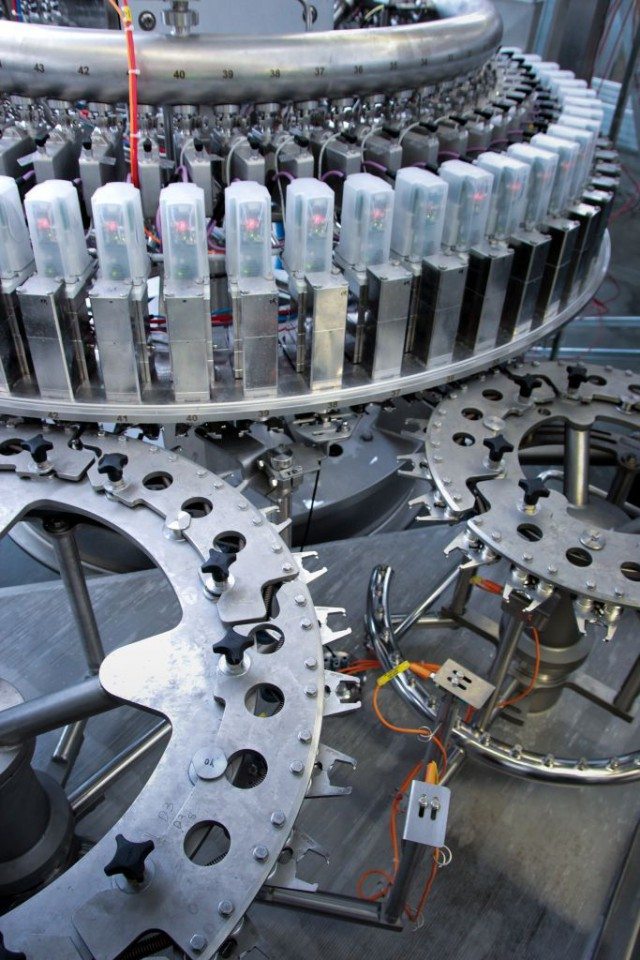

The second line reaches a speed of 48,000 bottles per hour (bph) and consists of a Sidel Matrix Combi, a Sidel Rollquattro Evolution labeler, as well as end of line equipment (shrink wrappers and palletizer).

The Sidel Matrix Combi is designed to reduce total operational costs by up to 12% compared to traditional lines.

It also occupies up to 30% less floor space compared with traditional equipment and gives producers more design freedom to differentiate their beverages while enabling bottle lightweighting at high speeds.

As it has one simple control interface, it requires only an operator.

Due to faster changeovers and minimal maintenance needs, the Sidel Matrix Combi also significantly increases production uptime and reduces operating costs compared to traditional lines.

“Although we already have one of the smallest environmental footprints in our marketplace, our company is looking to further improve its sustainability by optimizing bottle design and lowering resource consumption,” said Dominic Hadeed, owner and MD of Blue Waters Products.

“Besides allowing us to use less raw materials by producing high-quality lightweight bottles, the Sidel Matrix Combi will also help us decrease our consumption of air, water, chemicals and energy, while the Sidel Rollquattro Evolution will allow us to use thinner labels and will help minimize our energy and glue consumption.”