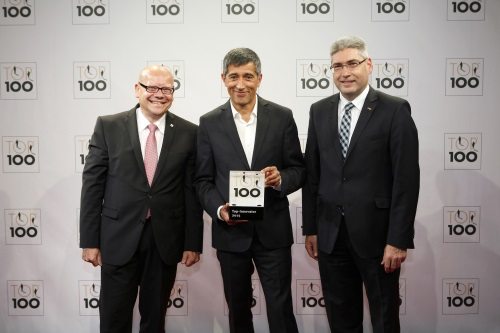

The KHS Group received the Top 100 Award for its successful innovation management at the 2015 German SME Summit in Essen, Germany.

KHS says it is very important to create a climate within the company which encourages innovation.

Certain groups of employees, for instance, are able to use 10% of their work time to develop ideas.

Inventor compensation and premiums act as additional incentives and are intended to encourage personnel to submit suggestions for improvements and innovations.

The many topics covered by KHS campus, the further training platform for KHS employees, include personnel development courses on various innovation skills, such as seminars on creativity techniques and method expertise.

Trainee program

KHS’ international Engineer4Future trainee program also offers extensive schooling on products and projects and provides expertise designed to encourage thought and action across the corporate interfaces.

The program is primarily geared towards engineering graduates with a PhD who have studied electrical engineering, mechanical engineering, information technology or similar subjects.

Right from the start trainees gain international practical experience and an overall understanding across the departments for the demands made of KHS products and services, enabling them to build up a personal network.

One of the program’s current team projects deals with the development of a crowd sourcing concept destined to strengthen the management of knowledge, ideas and innovation throughout the company.

Pioneering technologies

One of KHS Group’s innovations pertains to lightweighting, which has resulted in the design of pioneering beverage packaging.

For instance, extremely lightweight polyethylene terephthalate bottles yield many benefits for both beverage producers and consumers with their optimum combination of economy, market acceptance and product quality.

In another instance, the company’s Nature MultiPack packaging system won the National German Sustainability Award.

The system does away with the need for film materials for beverage packs, thus enabling resources to be conserved and the amount of waste produced by consumers to be reduced in the long term.

Using the KHS everywhere app, users can retrieve information on the status of their filling and packaging lines or single machines on their smartphone – at any time and wherever they are in the world.