The Asia Pacific region is marked by a growing middle class and greater health consciousness among consumers, which has given rise to opportunities in the areas of convenience and functional food, as well as automation and corporate social responsibility.

Singapore has been ranked alongside Hong Kong and Australia as one of the three major eating capitals in the region, which currently accounts for 40% of the total market share of functional food.

These changing demands, coupled with a wide range of transportation and storage facilities that differ across Asia, makes it difficult for enterprises to ensure that they maintain the quality of their produce.

Manufacturers have to ensure that their existing processes allow them to fulfil orders in an efficient manner – from managing the short shelf life of fresh produce, to pinpointing an exact source of contamination when a fault in the production line happens.

Handling information

2015 is poised to herald an era of smarter opportunities for this industry, coupled with the sheer amount of information that connected devices can collect and transfer into useful business information.

A global Internet of Things (IoT) study by Forrester Consulting in 2014 revealed that senior information technology (IT) decision makers inside key industries like food manufacturing believe that the IoT is transformational.

In short, Asia-Pacific enterprises believe that IoT will change the way their businesses around the globe are managed, while empowering their enterprises with the needed intelligence about their internal operations for them to improve business processes and better serve customers.

Exploring real time and location tracking

Enterprises today recognize the need for full, real-time visibility of their products as they move through the supply chain, from procurement to purchase.

One of the best ways to address the need for visibility in the supply chain is through the implementation of IoT technologies such as radio frequency identification (RFID) and real time location services (RLTS) that can provide enterprises greater visibility over the entire supply chain, and better manage their assets.

Adopting IoT technologies

One of the biggest implications of the adoption of IoT technologies is that firms will be able to gain visibility over their entire supply chain, improve maintenance operations and streamline efficiency.

- Improved food traceability and warehouse management

With RFID and RTLS technologies, enterprises will be able to better track their assets and find out where exactly they are, and what condition they are in from the harvesting of raw constituents, to food preservation, packaging and transportation.

Having an overview of the supply chain will allow enterprises to correctly identify areas of the supply chain that are causing delays ensure that even perishables get to their on time and in the freshest state possible.

- Accelerate recall and simplify returns management

Distributors need to have plans and processes in place to execute recalls quickly and efficiently.

The degree of traceability suppliers and distributors have over their products is what determines the size, scope and expense of a recall.

Having clear visibility over the entire supply chain allows for product recalls can be completed in a more expeditious manner as the source of the problem in the manufacturing process can be detected almost instantaneously.

- Tighten container management and fulfilment of shipping orders

An IoT-enabled system can generate information and provide useful insights that can help enterprises make better decisions on how to drive their businesses forward.

The amount of time saved from decreased manual labor can allow employees to engage in more meaningful tasks, and focus on providing quality service to their customers.

For example, a timely view of inventory can increase load yields for shipments, and essentially reduce the need for expensive less-than-truckload (LTL) shipments to customers to fulfil orders, and contribute to cost savings.

As it becomes imperative for companies to reduce the instances of disruption to their businesses, they will start to appreciate the premise behind IoT technology to gain real-time visibility into assets, people and transactions, and drive more effective and timely business decisions or to improve customer interactions.

Future trends

The following technology trends are expected to develop in 2015 and drive enterprise asset intelligence, innovation and influence decision-making around IT investments in the food manufacturing industry.

Trend #1: IoT

The intelligent enterprise will make IoT accessible and scalable for operations of various sizes, and seek to provide integrated visibility and connectivity solutions for their industries.

Research firm Gartner stated that 4.9 billion connected ‘things’ will be in use and is up 30% from 2014 and by 2020 there will be more than 20 billion connected devices in use.

2015 will see an uptake in this trend in response or anticipation to rising pressure to incorporate more intelligent functionality into devices, to enhance relationships, empower processes, optimize costs and mitigate risks in the enterprise.

Trend #2: A connected mobile workforce

Mobile technology and smartphone apps will continue to have a positive impact on professional and personal lives.

As more workers become less confined to a physical work space, enterprises will adopt tools to allow them to use cloud-based applications fed with real-time information about assets in their environment.

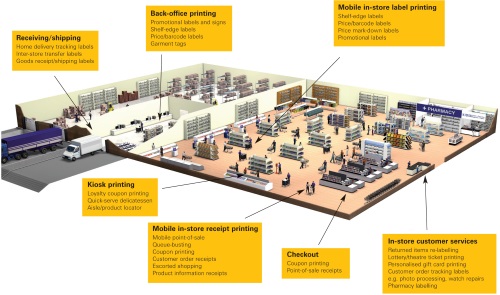

For example, shipping and receiving workers equipped with mobile computers, bar code scanners and label printers can receive inbound shipments, and log them into the host warehouse or inventory control systems with the mobile computer.

This allows workers access to key information in real time so that they and their customers can gain greater visibility into their extended value chains to improve critical business processes.

Trend #3: The adoption of cloud technology

The evolution of cloud technology is another major trend that has permeated the market over the last couple of years, impacting every aspect of IT and how users access applications, information and business services.

With the growth of smartphone-based cloud applications especially, the demand for rugged-connected devices will continue to expand.

The accessibility that cloud technology allows for example, will allow manufacturers to implement whole-chain traceability across warehouses around the globe, and oversee entire manufacturing processes from the grower, through the distributor, to the retailer.

Facilitating IoT solutions

Of firms surveyed globally by Forrester, 83% identify Wi-Fi infrastructure and real-time location tracking technologies as important or very important building blocks of IoT solutions.

As the adoption everyday objects connected to the Internet becomes ubiquitous, and workers’ demand for real time intelligence about all of their critical assets increases, enterprises will turn to cloud-based platform software that provides integrated visibility and connectivity solutions to make their processes more efficient, and work more effective.

Firms have identified the top five benefits of deploying IoT solutions in the enterprise to be improved customer satisfaction, supply chain optimization, visibility, loss prevention and cost efficiencies.

Tighter traceability does not have to burden business.

Companies in the food industry can take advantage of proven traceability tools and techniques to improve food safety and tighten their own operations by driving out excess inventory, storage, and handling costs.

These benefits can result from improved identification, which is accomplished most efficiently through the use of IoT-enabled tools and systems.

Story by Ryan Goh, VP of Sales, Zebra Technologies Asia Pacific.