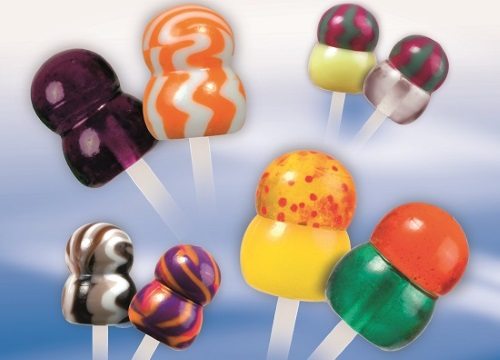

Baker Perkins has extended the appeal and diversity of lollipop production by developing one-shot technology for depositing double-ball lollipops on its ServoForm range of depositors.

This results to a totally spherical; conventional ball and flat lollipops.

Shaped, three dimensional and embossed versions of the flat product have been produced.

Existing depositing systems can be adapted to produce double-ball products by fitting new sets of molds.

The range of product options includes one to four colors, center-fillings, stripes, layers, inclusions, sugar-free and sugar options.

More innovative choices are created by the application of existing “short” and “long -term” layering capabilities.

For ‘short-term’ layered candy the second layer is deposited immediately after the first layer.

Syrups are mixed at the interface, but by carefully matching the deposited weight to bottom cavity volume, which does not detract from the appearance of the final product.

‘Long-term’ layered candy requires a depositor with two depositing heads spaced apart.

It involves a dwell time between each deposit, allowing the first level to partially set before the next one is deposited.

This ensures that there is clear separation between deposits allowing each layer to involve different colours, flavours, patterns and fillings – contrasting or complementary.