The dietary laws that forbid Jews and Muslims from consuming pork date back millennia, but when pork ingredients are included in food products, deliberately or accidently, consumers usually lack the proper detection tools to verify its existence.

Thus, food producers and merchants are entirely accountable for this and should always keep up the good practice of sending food samples for halal testing.

In May 2014, Cadbury is the latest brand to have found itself with a tainted food issue in that certain chocolate products were found to contain trace elements of pork deoxyribonucleic acid (DNA) in Malaysia.

This discovery caused a national outcry and led to a massive recall of Cadbury chocolate bars.

Even though in the end, the test results served Cadbury justice by testing negatively for containing porcine DNA, it is still mind-boggling to consumers how traces of pork could find its way into food products.

It is always helpful for the consumers to know how halal-testing is done.

The ABCs of halal testing

First of all, “halal” applies not only to meat and poultry, but to other food products, cosmetics and personal care products.

In the food supply chain, there are many stages from raising the animals all the way to reaching the consumers; any violation of Halal practices or contamination in the supply chain will automatically make the end product “Haram” – prohibited.

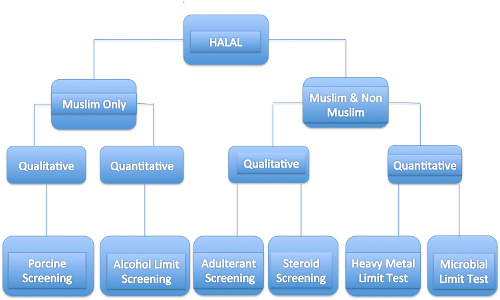

There are two major aspects to halal testing – Syariah Testing for Muslim only, and Safety Testing for both Muslims and Non-Muslims.

Under both branches, we place significance on porcine screening, adulterant screening (for men’s health products) and steroid screening (for cosmetic products).

Porcine DNA in food products

Pork-based products are not only limited to meat but can also be found in gelling agents in foods.

For instance, gelatin is often used in a wide variety of applications including food processing, pharmaceutical, cosmetics, and so on, generally functioning as a stabilizing, binding, thickening, emulsifying or foaming agent.

Gelatin can be found in many food products including jellies, ice cream, confectionary, cookies and cakes, in the pharmaceutical and cosmetics industries, gelatin is usually present in capsules, tablets, lozenges and cough drops; and it is an ingredient in skin drugs for external application.

Gelatin is made from collagen, a protein, which has been extracted from the skin, bones, and connective tissues of animals such as cows, chicken, pigs and fish.

After extraction the collagen is partially hydrolyzed to form the gelatin which is a mixture of peptides and proteins and is used in the form of sheets, granules or powder.

Mass spectrometry for porcine DNA testing

As the tolerance level for porcine content in foods is zero for religious reasons, the limit of detection (LOD) needs to be as low as possible so the continued development of more sensitive methods is necessary.

There are different methods used for halal testing, but they are all associated with various limitations.

This article will focus on how liquid chromatography mass spectrometry (LC-MS/MS) is able to generate testing results with high speed and increased accuracy.

LC-MS/MS can detect or identify proteins present in a food product.

Protein testing is considered as reliable for two reasons.

First of all, the primary structure of proteins is generally stable against processing; secondly, a limited degree of protein degradation is less critical than the equivalent amount of DNA shearing.

In the mass spectrometry world, scientists or laboratory personnel study the multiple peptide markers containing protein sequence information to determine if a food item is adulterated and what the adulterant is.

Step 1: Sample extraction, clean-up

Gelatin samples are extracted and dissolved in ammonium bicarbonate buffer; the extract is digested using trypsin in a trypsin to sample ratio of 1:100.

Digestion takes place either overnight at 37 degrees for 10-15 hours or using a microwave burst technique where the samples are placed in ice and subject to 5 x 30 seconds of microwave digestion, between each microwave burst the sample was shaken.

Once digested the samples are spun at 12,000 revolutions per minute (rpm) for five minutes.

The top supernatant layer is removed carefully, not to disturb the bottom sediment, and centrifuged again at 12,000 rpm for another 5 minutes.

The top portion of the supernatant then is used for analysis.

Step 2: Separating the compounds

Once samples are amassed and cleaned, they are put into a combination of a mass spectrometer and a separation instrument to separate the peptides using a 45 minutes gradient at a flow rate of 250microliter per minute or µL/min.

Step 3: Identifying the compounds

An information dependent acquisition (IDA) method is used to automatically trigger 30 spectra from the information in the mass spectrometer’s survey scan; a software designed for metabolomics and protein/peptide biomarker profiling applications is then used to activate principle compound analysis to identify characteristic markers for gelatin speciation.

Step 4: Optimizing markers

From this experiment several markers will be identified, which then are transferred to another mass spectrometer where multiple reaction monitoring (MRM) transitions for each marker are optimized.

Step 5: Generating and comparing results

Trypsin extracts produced from beef and pork samples using this method are compared and marker peptides which have different sequences and generated different MRM and fragmentation patterns could be produced.

Beef gelatin is then spiked with pork gelatin so that levels of contamination of beef with pork gelatin can be determined.

Conclusion

By using this method and LC-MS/MS systems, gelatin ingredient can be extracted and analyzed in less than one hour.

Even a small amount of pork gelatin in processed food such as sweets or those used in pharmaceutical capsules could be identified.

In the future, lower detection limits will be possible with the use of more sensitive LC-MS/MS systems, which mean that gelatin speciation at even lower levels is possible.

This will undoubtedly alleviate ethical concerns of the source of gelatin used in food manufacturing and pharmaceutical capsules used to deliver drugs.

Story by Lauryn Bailey, PhD, global marketing manager, Food & Environmental Markets, AB SCIEX.