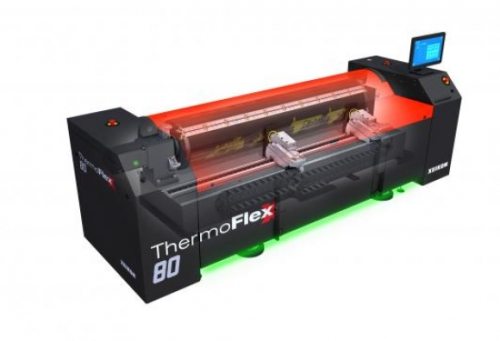

Xeikon’s ThermoFlexX 80 is the first in-house designed and manufactured model in its imager range since the company acquired FlexoLaser in 2012.

Available from August, the machine has a dual-head imaging feature with output speed of 12 sqm an hour at 2,400 dots per inch (dpi).

With three independent, replaceable modules – the motor, laser and optics, the machine simplifies service and hardware upgrades, while providing the possibility for remote optical fine-tuning.

The optical system has improved imaging quality with a maximum resolution of 5,080 dpi.

To overcome the need to handle plates manually, which is one of the main causes of plate damage, the machine has Flextray that can be adjusted easily to transport and feed plates into the innovative guiding system.

This ensures that plates as thick as 6.35 mm can be seamlessly mounted on the drum.

All ThermoFlexX imagers utilize IPG fiber lasers operating at 1,064 nanometer (nm), which combine low energy consumption with high reliability.

The imagers will expose any plate with a laser-ablatable mask or LAM layer such as flexo, letterpress and dry offset, as well as Gallus Screeny (digital screen) and ablative film.

They can handle thickness from 0.18 mm ablative film to 6.35 mm flexo plate, and support all relevant technologies such as flat top dots.

This means that if a printer uses plates from suppliers such as Flint, DuPont, Asahi, MacDermid, Toyobo and Toray, they can continue without changing their normal working practices.

ThermoFlexX imagers accept 1-bit tagged image file format (TIFF) files generated by any workflow, raster image processoror RIP or front-end and will handle any innovative screens such as hybrid or surface screens.

The screened 1-bit TIFF file could be a single job file, which can be assembled on a template, or it could be an already assembled 1-bit TIFF plate.

These imagers can be integrated into existing workflows such as those from Esko Graphics, Hybrid Software, Kodak and Agfa.