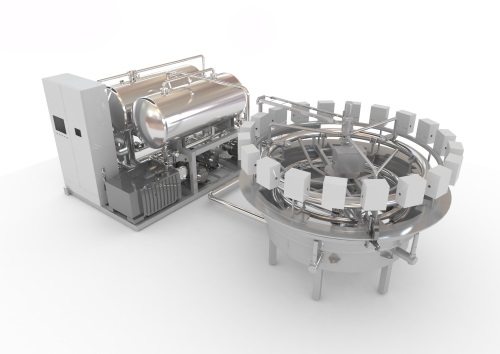

SIPA has used the Flextronic flexible and modular platform and launched new filling valves in EVO versions for integration and interchangeability into the new platform.

Through this combination, the company aims to design solutions for various bottling requirements such as filling multiple products on the same line.

At Drinktec 2013, SIPA showed Flextronic C, which can handle carbonated, still and hot-fill products, with or without pulp, on the same line.

The system can also handle various types of containers by switching from one neck size to another.

The filler was exhibited in its Xfill configuration, which has no on-board product tank.

When it is used for carbonated drinks, the mixing unit tank is used as a buffer tank.

The integration of the mixing unit with the filler enables the packaging of a quality and stable finished product while improving the entire filling process.

Using the new valve and Xfill configuration, there is operational flexibility, reduced product loss and downtime in flavour change.

Managing filling process electronically

To reduce power consumption, a new concept was incorporated into the entire filling process electronic management.

It also reduces the amount of carbon dioxide used when filling with carbonated drinks and product losses from the shift circuit.

“What we were aiming for was a new generation of fillers that would stand out with their versatility, high performance, ease of use and maintenance, in a complete system characterised by extreme cleanliness,” says Federico Zannier, Filling Line Sales Manager.

Easy maintenance

“With this platform we are introducing several new developments while retaining key advantages of the previous generation of fillers,” says Renato Le Brun, R&D Manager, Filling Division.

“Made of 316L stainless steel, the valves are solid and compact. They have been designed with a clear separation between the pneumatic components and the parts that re in contact with the product, in order to avoid any problems with contamination,” says Le Brun.

“They are made up of a series of elements that can be separated without disassembling the entire valve, so maintenance is simpler and faster.”

Compared to its predecessor, the company says Flextronic C has improved stability of the product during filling that is particularly important for carbonated drinks.

In addition, the new valve has larger channels for the passage of carbon dioxide, for improved operation with liquids containing pulp and fruit.

The valve has been designed for “dry” pressurization via a separate channel for faster and steady decompression.

By incorporating Flextronic C into SIPA’s SincroBloc blowing/filling monobloc, there is no need for bottle rinsing while enabling improved control over the entire filling process for improved filling performance.