The notions of ‘Made in China 2025’ and ‘Industry 4.0’ have encouraged Chinese manufacturers to embrace smart production, according to Chinaplas 2016 organizer Adsale Exhibition Services.

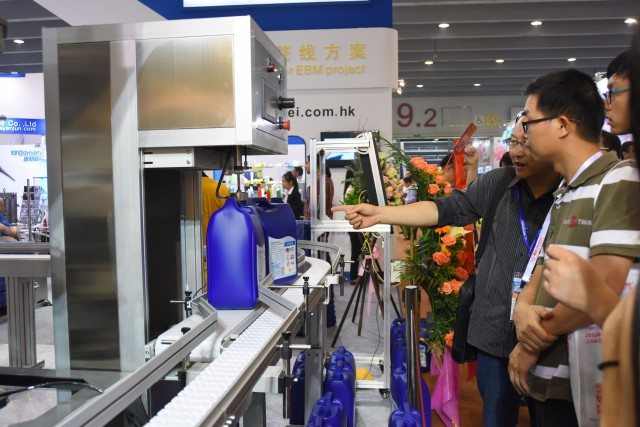

Many companies have started integrating robotics, digital network and automatic equipment into their production lines, from sorting and picking, precision wielding, packaging, inspection, storage and to transportation.

These increase productivity and precision, consume less power and cut production cost.

For example, Bosch’s D3 robotic packaging solutions use Paloma D3 feed and top-mounted robot to integrate into Module ++ biscuit packaging production line.

This robotic platform handles higher payloads up to 3 kg and increases pick rates.

Demag’s El-Exis SP 200-67 can produce four polypropylene (PP) food container injection molding (125 ml) with production cycle of less than two seconds, which is 3-5% shorter than the standard production cycle time.

The final product is picked up by a robotic arm.

China’s Guangdong Guozhu Precision Mold has a high speed injection molding system that can produce 600,000 high-density polyethylene bottle caps per day, each weighing 1.95 g.

NatureWorks’ Ingeo, a plant sugar-based polymer derived from natural resource, is biodegradable that maintains similar mechanical strength and heat resistant properties as the non-biobased polymers.

For the food industry, Milacron’s cooking can, Klear Can, can withstand heat up to 130°C and its three-layer plastic construction (PP-ethylene vinyl alcohol-PP) offers a shelf life of two to five years.

A co-injection system was used to produce the transparent food can, with which the consumers can see the contents and in-mold labels

Held from April 25-28, 2016, at the Shanghai New International Expo Centre in Pudong, China, the show will be expecting 140,000 trade visitors from 150 countries and regions.