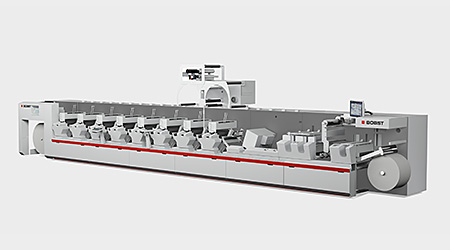

BOBST presents its new M4 press (430 mm width) for printing labels and flexible packaging and mid-web press M6 press (670 mm width) at Labelexpo Europe 2015.

At the event in Brussels, Germany from September 29 to October 2, 2015, the company will show the Digital Automation program in the print cylinder configuration for M4 and in the print sleeve configuration for the M6.

During the show ‘live’ exchange of multiple jobs with less than 10 meters of substrate waste and one minute of set-up time will be performed.

For the REVO Project for 7 Colors Extended Gamut technology, BOBST will host the full REVO plate manufacturing process with new plate manufacturing and printing ‘live at the show’.

New sets of plates will be produced and used for printing jobs on both presses every day.

REVO Digital Flexo and BOBST Digital Automation will prove that traditional digital and digital flexo process are comparable for flexibility in running short runs, with clear economic advantages for digital flexo.

At the show, the REVO Team will introduce the concept of non-stop digital flexo with the aim to achieve up to 95% press up-time.

To achieve this objective on the new M6, BOBST automatic turret un-winder and re-winder will be shown.

On both M4 and M6 presses BOBST Excellence Technology will allow for fully automated job exchange on-the-fly without stopping the press.