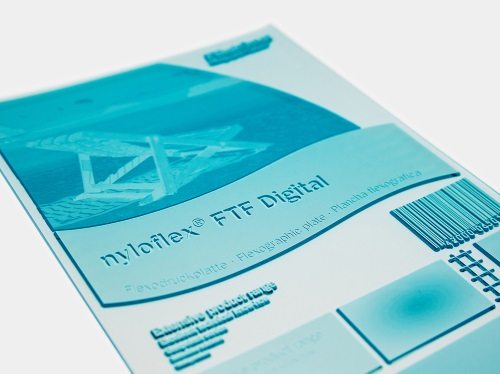

Flint Group introduces nyloflex FTF Digital – an inherently flat top plate with special, textured surface for flexible packaging.

The company says flat top dot and surface screening technologies provide high quality print results in flexo printing, but the reproduction still requires a complex prepress process and extensive plate making with additional steps and equipment.

FTF stands for Flat Top Dot plate for Flexible Packaging.

The new flexo plate provides flat top dots by simply processing it like any standard digital plate without any change and additional equipment, processing step or consumable item.

A special, textured plate surface eliminates the need for time consuming surface screening.

The texture of the plate provides an even ink laydown and increases solid ink density with just a standard resolution of 2,400 or 2,540 dots per minute.

This reduces complexity and increases efficiency in the prepress and plate making process.

nyloflex FTF Digital plates display the advantages of flat top dot geometry, such as less dot gain variation resulting in improved production consistency, as well as a reduced bump-up, while reaching the first stable tonal values of 1.2% at 60 L/cm (152 lpi), thereby increasing image contrast.

Extensive field trials showed a significant improvement of the typical trail edge void effect with the use of the nyloflex FTF Digital plate.

The new photopolymer flexo printing plate, nyloflex FTF Digital, will be available to the market in the thicknesses of 1.14 mm (.045”) and 1.70 mm (.067”) in July 2015.