Singapore aims to meet up to 30% of its future water needs by 2060 with desalination: removing salt from the abundant seawater that surrounds it.

The country currently uses reverse osmosis for its desalination, which produces pure drinking water by pushing seawater through membranes to remove dissolved salts and minerals.

However, fouling of the membrane can cause expensive downtime or costly repairs for desalination plants, meaning that the process still has room to become more cost effective.

New solutions are also needed to reduce the impact of desalination on the environment. PUB, Singapore’s national water agency, wants to cut in half the energy needed for desalination in the future.

Additionally, programs to mitigate fouling that use conventional technologies can result in the growth of harmful algae in aquatic environments.

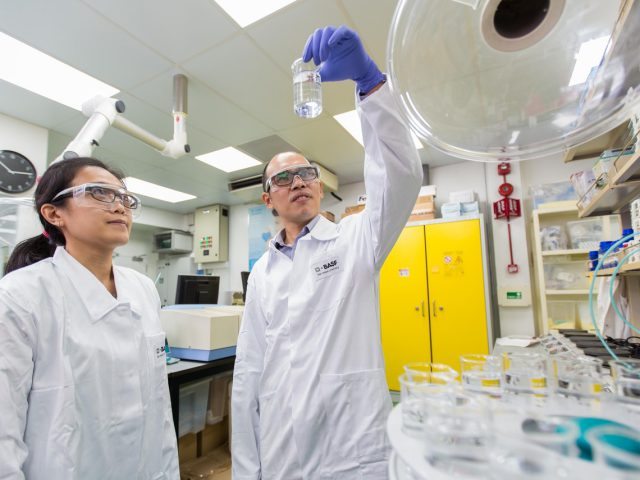

To co-develop solutions with desalination experts in the region and offer analytical supports, BASF has relocated and expanded its desalination laboratory in Tuas, Singapore. The new laboratory is now fully operational with chemicals, lab consumables, equipment and analytic.

The laboratory aims to maintain the high level of productivity of desalination plants, and protect these high-investment facilities from scale formation and fouling.

One recent development example from BASF is Sokalan RO 3500, which has been proven to work on a variety of membranes and types of water.

Compared to conventional antiscalants, this solution does not cause eutrophication and its resulting growth of algae.

Desalination is a vital way to ensure Singapore’s long-term water availability.

With new technologies like these, desalination may soon live up to its promise while maintaining a lower environmental impact, and more cost-effective operations.