Why would you dress a ground-breaking formula in last year’s trends?

Tailor-making a bottle, compact or tube can take many turns, from a subtle addition of a vogue-ish cap or sheath, to an avant-garde decoration treatment or a new, high-tech dispensing system that will become a benchmark in the industry.

In a cluttered marketplace that is constantly searching for the ‘next big thing’, bespoke package design adds differentiation and a competitive edge.

Each bespoke project is unique, but there are always certain steps you need to take to turn your vision into reality, says Quadpack designer Rubén Caño.

Stage 1: Discover

A new design is born with an idea that fills a particular need.

The packaging provider works from inspiration from the client or hatched within its design department.

Either way, this inspiration should reflect the current consumer mind-set, based on market research and trends analysis.

In-house brainstorming is needed to flesh out the concept.

It must be original, on-trend and meet consumer demand.

Technical possibilities must be explored, along with advances in other manufacturing industries that could be applied to the beauty packaging sector.

Stage 2: Define

To define a new product ask questions like What is it? What function will it provide? Does it fulfil a real need?

A brand should be completely clear on how its product will look, how much it will ultimately cost, and all the viable options in terms of shape, volume capacities, dispensing systems, materials, finishing and decoration.

To do this, a brief is drawn up that outlines every single requirement, from the technical to the aesthetic.

The more detailed the brief, the more successful the project.

Stage 3: Design

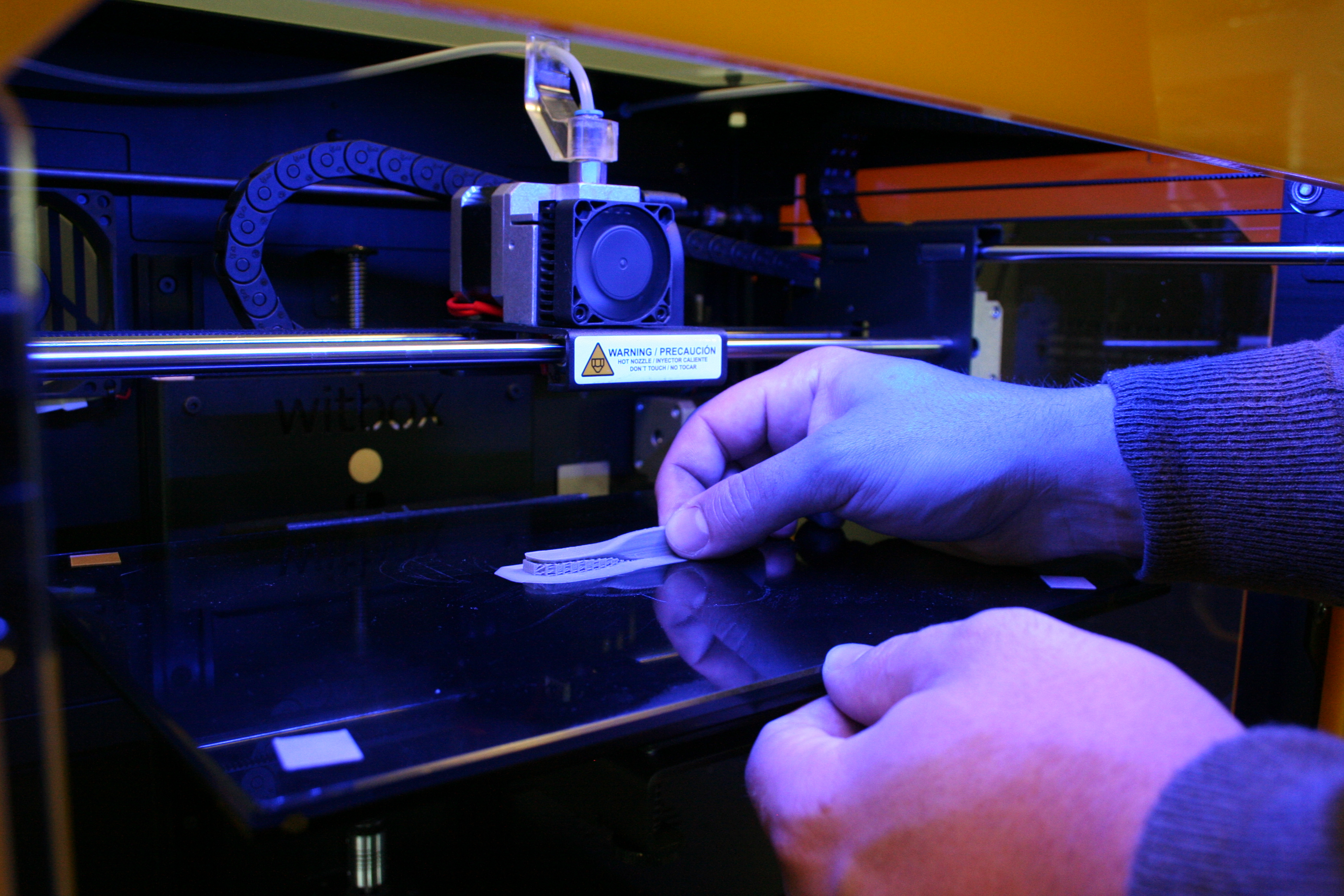

Using high- and low-tech tools, from hand drawings to rendering software, the design team and packaging engineers then offers the client some alternatives within the definitions of the brief.

Shapes are experimented with and decoration and printing options explored, often in collaboration with in-house specialists, involving external suppliers where necessary.

These could include advanced screen-printing options, surface treatments for glass or plastic, or perhaps the additions of wooden components (a cap or sheath).

Stage 4: Refine

This stage involves lots of discussion between the design team and the client – hashing out a final vision from the ideas cloud that was generated in the previous stages.

Shapes, dimensions and finishes are refined and tweaked with the designers, costs pinned down with product managers and engineers step in to ensure the technical criteria is being met.

During this stage the client is presented with three dimensional renders based on technical drawings.

If a mold already exists, a prototype will be presented.

If not, it will come at the beginning of the production stage.

Stage 5: Produce

With the project and all its technical aspects locked down, it is ready for industrialization.

Schedules are approved and manufacturing facilities prepared for the technical requirements and production volumes involved.

If a new shape has been created, so must a mold.

When this is done, a low-quantity test run must first be carried out, so that the client can approve the samples.

A compatibility test may need to be taken with the formula.

Lab technicians test for functionality and any adverse effect due to a formula’s water and alcohol content.

If the client does not have lab-testing facilities, a packaging provider will be able to carry out this process at additional cost.