With the arrival of the Industrial Internet of Things, manufacturing sectors have already begun to invest in highly automated and information technologically-driven production, transforming traditional factories to smart factories, says organizer of Chinaplas 2016.

The show will be held from April 25-28, 2016 in Shanghai, China.

Undoubtedly, ‘automation’ is the major element in smart manufacturing technology adoption process, to improve resources utilization, customer service, working capital deployment, waste reduction and sustainability.

Real time communication between machines, factories, logistic providers and suppliers provides improved visibility on the end-to-end supply chain.

According to the global market research firm TrendForce, the global market of technologies involved in smart manufacturing or factories is estimated to reach US$250 billion in size by 2018.

The intelligent manufacturing is going to cause a revolution in manufacturing industries in the next decade is not a far-fetched projection.

The plastics and rubber industries will certainly be part of it, as technology upgrade is already on the go among these factories.

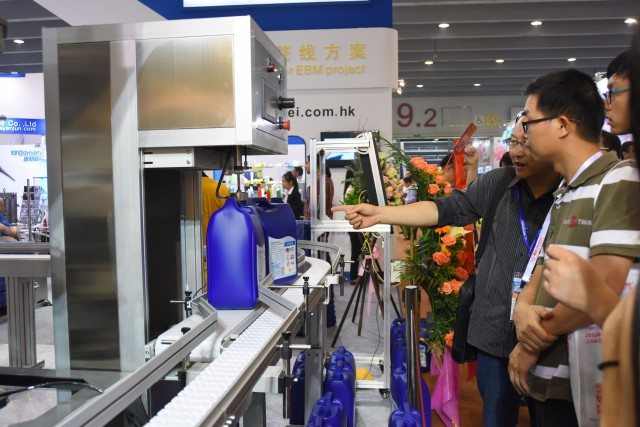

With smart manufacturing trends, the Automation Technology Zone at the show will grow in scale with the introduction of Factory Automation System and Components Zone in addition to Robot Parade and Smart Production Line.

Sumitomo (SHI) Demag Plastics Machinery (Nignbo) Co., Ltd. will launch for the first time in Asia its Systec Servo 210, a complex production unit for insert molding and technology, as well as in-mold decorating uni-directional (UD) tapes, with their partners the German automation specialist M.A.i GmbH & Co. KG of Kronach, the decorative foil specialist Leonhard Kurz Stiftung & Co. KG of Furth and plastics processor HBW-Gubesch GmbH of Emskirchen.

This all-in-one insert-inject-weld-detect integrated automation system combines the complex structure and the decorative functions of technology products, which are lighter, more functional, stronger and more attractive.

Energy consumption and material consumption are also reduced.

Their demonstration will include décor pick-up station, UD-tape pick-up with hot handling, metal insert at ejector side, décor insertion, UD-tape insertion and mounting station.

Specifically, a small pair of gram-weight pliers will be seen manufactured to possess better strengths after the treatment with UD-tape, and the final product will be lighter than similar products by 35%.

The system can be applied in the automotive industry for producing semi-structured optical products.

Meanwhile, Dongguan Enmair Automation Machinery Co., Ltd. will be hosting live demonstrations of their EM series of multi-joint, multi-axis robots, which are fast and precise full servo robots equipped with five to nine servo motors with working repeat positioning accuracy of within ±0.1mm.

Switek Technology Automation (Dongguan) will display a set stack mold automation/packaging systems with SWITEK&WEIDA for the first time.

This apparatus is made for fold mold, output of which can double that of a normal speed machine, saving 60% electricity.