Veolia Water Solutions & Technologies (Thailand) will be providing Associated British Foods (Thailand) or ABF a full turnkey wastewater treatment plant.

This project integrates several of Veolia’s innovative technologies – including its Dissolved Air Flotation (DAF), Biothane Upflow Anaerobic Sludge Blanket (UASB), AnoxKaldnes Biological Activated Sludge (BAS), and Hydrotech Drumfilter – within ABF’s Ovaltine manufacturing plant in Samutprakarn, Bangkok.

With this end-to-end wastewater package, ABF will be able to handle its wastewater treatment needs on premise, catering to both existing and future flow requirements projected for the next decade.

Faced with the challenge of designing a wastewater treatment plant located within the client’s space constrained manufacturing grounds, Veolia recommended key technologies that could effectively treat their wastewater volumes and chemical oxygen demand (COD) loads.

Meanwhile, Veolia’s DAF unit pretreats the raw wastewater, removing fat, oil, and grease (FOG) before the Biothane UASB anaerobic treatment process.

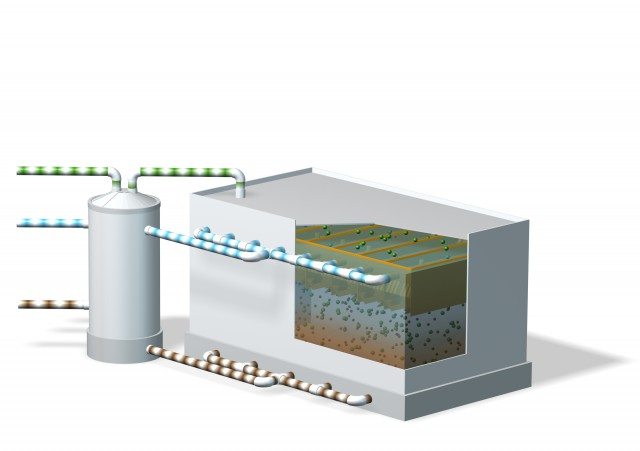

The UASB anaerobic system then converts COD present in the conditioned wastewater into biogas.

Veolia’s AnoxKaldnes BAS, a combination of Moving Bed Biofilm Reactor technology with conventional activated sludge, is next applied to promote a stable and more efficient activated sludge process with improved sludge settling characteristics.

The effluent then enters a second DAF clarifier unit for biological sludge separation, before the Hydrotech Drumfilter system separates the remaining particles from the wastewater.