Netstal presents injection compression molding on a stack mold at Fukama 2015.

This innovation will be demonstrated using a 15 oz margarine tub made from polypropylene that is manufactured with 4+4 cavities on an Elion 2800-2000 and weighs 10.7 g.

Working with mold manufacturer Plastisud, automation specialist Machines Pagès and Swiss injection molding manufacturer Netstal, the injection compression molding process and the stack mold technology were brought under the same roof.

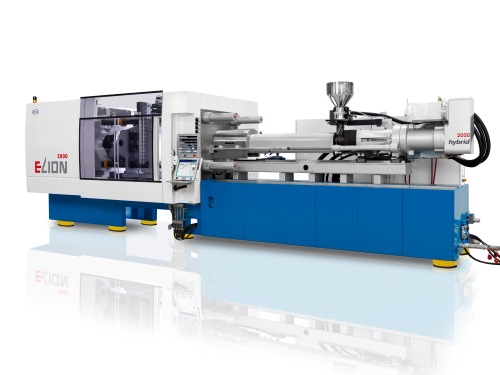

It appears almost trivial at first sight: a slightly modified injection molding machine from the Netstal Elion Hybrid series molding margarine tubs in standard format 15 oz with in-mold labeling decoration in a cycle time of five seconds.

On closer inspection, it turns out that the process is performed in a stack mold with 4+4 cavities.

“The really revolutionary thing about the whole process is hidden from view: the polypropylene packaging is not injection molded but manufactured in an injection compression molding process,” says Markus Dal Pian, VP, sales & marketing at Netstal.

The cavities are partially filled in 100 ms with even results and the process is performed at a low pressure to prevent tension in the material.

The high quality of the platen parallelism guarantees a synchronicity of 99.98% between the mold, machine and automation system.

In just a few months, Plastisud developed a stack mold specially adapted to the requirements of the new production process.

The fundamental benefits of injection compression molding include narrow wall thicknesses and a lighter product resulting in lower unit costs.

Furthermore, the end product (lids in particular) shows fewer signs of distortion and has a greater dimensional accuracy due to the lower stresses placed on the material.

These properties make the end product much more attractive for packers such as margarine manufacturers compared to other processes.

For the packaging manufacturer, there is a significant increase in productivity through the use of a stack mold and drastic reduction in material costs by up to 20%, as well as total flexibility in terms of shape, appearance and decoration of the manufactured part.