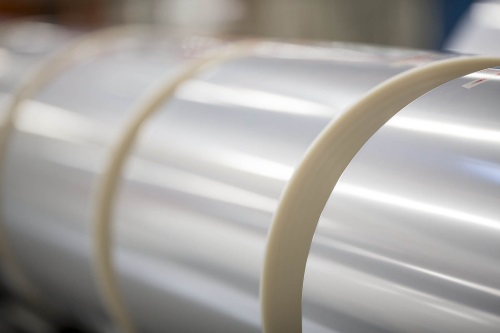

Biaxially oriented polypropylene specialist Treofan features an innovative surface that enables stable fusing of thermoforming and label film at comparatively low temperatures and pressures, allowing the benefits of deep drawing to be harnessed without compromising quality.

The company says deep drawing – or thermoforming — is an increasingly popular alternative to injection molding for certain product groups due to potential economies of scale.

Until now, however, attaching BOPP labels to thermoformed products has required a process step; as temperatures and pressures used in thermoforming are much lower than those in injection molding, direct fusion is not possible.

Treofan’s special surface attaches to deep-drawn films under the conditions typically used for thermoforming.

The resulting join between container and label is visually and functionally near-indistinguishable from the complete fusion achieved by injection molding.

Following a comprehensive series of tests — including with Illig, a provider of machinery and tools for thermoforming and packaging technology, the new label film is now available in the market as Treofan EPT.