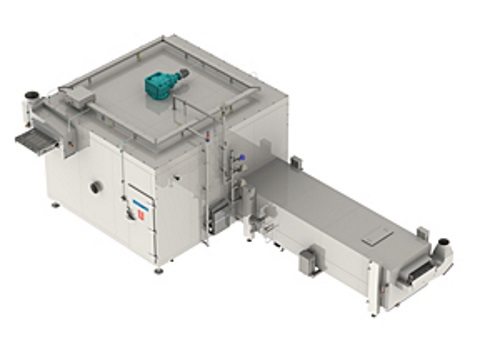

Linde North America’s new immersion spiral freezer is a two-stage cryogenic freezer that can process more than 20,000 pounds per hour.

The first stage applies an instant crust freeze with liquid nitrogen to maximize yield and protect surface integrity.

The cold gases from the first stage travel into the second stage to maximize the use of British thermal units or BTUs for low operating costs.

Key uses include:

• Marinated, cooked or raw, poultry, red meat and pork products that require a solid freeze, including diced meats, fillets and fajita strips, bone-in and boneless chicken and turkey breasts, drumsticks and wings.

• Glazed and marinated products.

Unlike conventional freezers, the immersion freezer works well with wet, sticky, glazed or injected and marinated products.

The bath of liquid nitrogen locks glaze onto the food product to maximize yield.

• Freezing scallops, shrimp, seafood fillets and shelled clams at high volume.