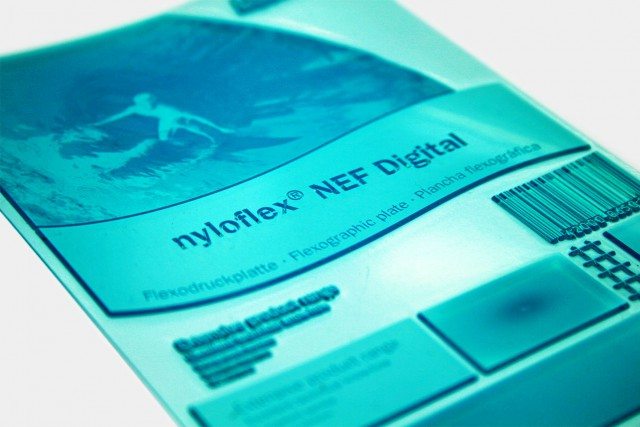

Flint Group Flexographic Products presents with nyloflex NEF Digital a new durometer plate that is designed for the nyloflex NExT exposure technology to print flexible packaging and labels.

Developed for the efficient creation of flat top dots and an excellent reproduction of surface screenings, the new plate shows quality in highlight areas due to a stable reproduction of highlights and smooth vignettes.

It allows for a reduced bump-up, while reaching the first tonal values of e.g. 0.8 to 1.2% at 60 L/cm (152 lpi), hence increasing the image contrast.

The ink lay-down can be significantly improved and a high solid ink density achieved when surface screens are applied.

The result is print performance on film, foil and coated paper substrates.

The short exposure and quick washout times enhance the productivity of plate processing.

Using the printing plate, flat top dots are less impression sensitive, enabling less dot gain variances on press.

With the nyloflex NExT exposure technology, no additional processing steps, such as lamination, or additional auxiliaries (like nitrogen supply or film materials) are required, says the company.

Although the nyloflex NEF Digital plate is especially designed for high-output ultra-violet light emitting diode exposure, it can also be exposed with regular tube light units.

Compared to other digital plates in the market, when the nyloflex NEF Digital plate is exposed with conventional tube light, it can reproduce flat top dots with surface screening patterns.

Though being less distinct than with the nyloflex NExT exposure, these screens enable one to achieve a more even ink lay down than reached when regular digital plates are used.

The digital plates require a lower bump up, which allows for the increase of grey levels in printing and the capability to increase the image contrast as compared to regular digital plates in the market.

The new photopolymer printing plate is available to the market in the thicknesses of 114 (.045”) and 170 (.067”) in the beginning of August 2014.