GEA OxyCheck was displayed at packaging show in Germany, interpack 2017, as the world’s first in-line measurement system that checks the oxygen content and seal integrity of every food product packaged in modified atmosphere.

Each modified atmosphere packaging (MAP) item is non-invasively inspected after sealing on a GEA thermoformer instead of having to be damaged by a needle as was general practice up until this point.

This makes costly spot checks obsolete, films and seals remain intact and there is no loss of product or materials.

As a member of the Save Food initiative, this is GEA’s contribution to reducing food waste during production.

Mechanism

Today, more than half of all retail fresh food – meat, fish, poultry, fruits and vegetables, confectionery and baked goods as well as dairy products – is packaged in a modified atmosphere.

During this process, a gas mixture of carbon dioxide and nitrogen is injected into a package prior to sealing. This slows down decay, thus extending the shelf life of the packaged product.

A small percentage of oxygen remains in the package by the process, but this may not exceed a threshold to avoid early spoilage of the goods.

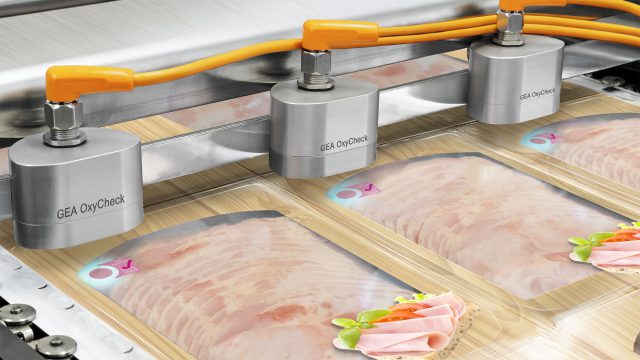

GEA OxyCheck carries out the important task of monitoring the residual oxygen content directly during production on the GEA PowerPak thermoformer.

The GEA technology uses a sensor spot made of a polystyrene-based fluorescent dye that is printed on the inside of the film.

Similar to an indicator strip, the wavelength of the dye changes depending upon the oxygen content inside the package.

Sensors on the GEA PowerPak thermoformer activate this sensor spot and then take a reading. GEA has developed a special method for calculating the oxygen concentration based on the light emitted and the temperature.

The new measurement system has no effect on either the line speed or the throughput of the GEA PowerPak.

Safe outcome

GEA OxyCheck has been approved by the US Food and Drug Administration and meets all relevant EU regulations for Food Contact Materials.

The liquid is similar to the materials used in making the packaging films.

The sensors work with the pulsed light of a light emitting diode, which is safe for both products and operators.

The process has no effect on either the composition of the modified atmosphere or the package content.

Initially designed for use on the horizontal thermoformers of the PowerPak line, GEA OxyCheck will also be available as an optional feature or retro-fit upgrade for other equipment with MAP capabilities.

In the future, GEA is planning to offer the system for other applications such as the vertical thermoformer as well.