Gebo Cermex receives the Vitrine Industrie du Future mark from the Alliance Industrie Du Futur (AIF) in recognition of its efforts to introduce, develop and implement Industry 4.0 initiatives at its plant in Saint Laurent sur Sèvre, France.

This mark is awarded by AIF to companies that implement new tools such as digital data exchange and advanced robotics to drive the transformation of business models and organizations as well as design and marketing methods.

Gebo Cermex recognizes the significant contribution made by its Virtual Commissioning project for the award – which was led by the team based in Saint Laurent sur Sèvre.

Key achievements – which helped the company to meet in full the requirements listed by AIF – included a 20-30% decrease in lead times and production costs; a long-term approach towards zero defects, dramatically improving quality and accuracy; and increased reliability, due to the ability to show customers, in advance, details about the performance of their equipment.

“A typical commissioning phase, when new equipment has to be physically assembled and tested in a workshop, takes approximately 200 hours with 46% spent in problem solving activities, and 54% covering testing and tuning,” says VP operations Christian Bock.

“The real innovation of our Virtual Commissioning project is that we are able to dramatically decrease the time and costs involved, while anticipating the challenges the equipment might face when installed in the actual production environment.”

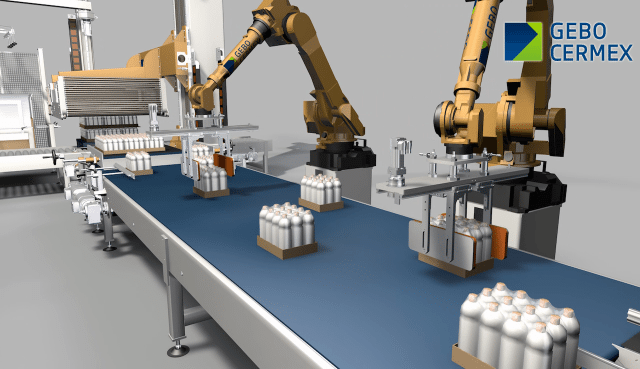

“Gebo Cermex engineers use advanced tools to virtually build the full machine, checking, in parallel, even the smallest details.”

“This allows them to export the virtual model in the simulation tool and to visualize how the equipment behaves.”

“The virtual 3D model can be viewed, operated and animated via a Human Machine Interface (HMI).”

“Moreover, the virtual commissioning allows for a 3D model to perform a big part of the de-bugging process ahead of installation and it is possible to simulate many scenarios in which the equipment might be working when integrated in the customer’s plant, without using the actual machine.”

Earlier this year, Gebo Cermex unveiled its Agility 4.0 program, designed to enable producers to manufacture small production batches at cost levels typically associated with mass production, without compromising on key performance criteria such as Overall Equipment Effectiveness, Total Cost of Ownership and sustainability, to name but a few.

It represents a proven, pragmatic approach to make the benefits of Industry 4.0 possible: from initial virtual design to total mastery of the extended factory, the Agility 4.0 program encompasses smart machines, system and data intelligence, digital connectivity and powerful simulation tools, all within a philosophy of sustainable production.