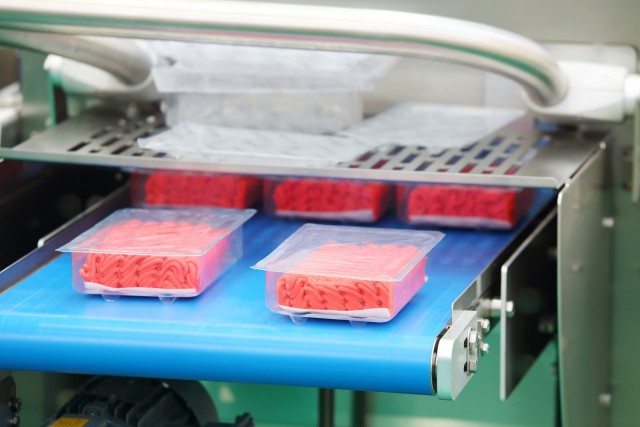

Over recent years, the range of fresh pre-packed meat available in the self-service areas of supermarkets has increased steadily.

Today, pre-packed meat products hold a market share of roughly 50%, and most of them are packaged in a protective atmosphere.

Oxygen causes surface discoloration, particularly on cut and pulped food products.

Given this, many food products are sold packed in a protective atmosphere, which means the composition of the internal atmosphere of the package has been modified.

In other words, during the packaging process for products such as cold cuts, cheese and potato crisps, the oxygen in the package is replaced by nitrogen or carbon dioxide.

Modified atmosphere packaging, or MAP, is on the rise.

The precise mixture of inert gases used depends on the individual case.

Meat: a special case

Where meat is concerned, colour is one of the prime quality criteria, with bright cherry red being a sign of freshness.

This red colour is caused by myoglobin, a muscle pigment which starts to ‘bloom’ in contact with the oxygen in air and forms oxymyoglobin.

Although the presence of this substance is desirable, when the level of ambient oxygen falls below a certain level it can change the colour of the meat to an unsightly brown.

To avoid this discolouration, food producers modify the atmosphere in the packaging of fresh red meat to ensure an oxygen content of at least 70-80%.

Under this atmosphere, meat maintains its colour and keeps fresh longer.

Modified atmosphere packaging thus extends the shelf life of meat.

However, once the MAP has been opened, meat should be prepared and consumed quickly.

Labelling

Modified atmosphere packaging of food products sensitive to oxygen must be declared on the food label, e.g. by adding the words ‘Packaged in a protective atmosphere’.

The package design must ensure that the atmosphere, i.e. the gas mixture, is maintained throughout the shelf life of the product.

“Good manufacturing practice (GMP) requires manufacturers to make sure that no chemicals or elements added to the packaging can migrate into the food product,” says Dr Andreas Daxenberger, food expert at TÜV SÜD.

“Manufacturers must exclude any risks to consumer safety and health and any unacceptable changes in odour or taste caused by substances used in packaging.”

This also applies to innovative intelligent packaging technologies, which utilise a colour-based oxygen indicator integrated into the packaging to provide a warning if the MAP has been tampered with or damaged.

Avoiding food loss and waste

When it comes to pre-packed meat products, consumers prefer transparent packaging.

However, the products packaged in this way are exposed to light without protection, which may also be a cause of discolouration.

As consumers reject discoloured food products, any products not sold in time usually have to be disposed of.

Consumers should take care to avoid any damage to the package during shopping, when bringing the products home or during freezing.

Story by TÜV SÜD.