As consumers increasingly demand highly desirable and nutritious food, the popularity of eggs continues to rise globally.

According to the Birtish Egg Industry Council, egg consumption in 2014 increased by two per capita to reach a total of 11.8 billion eggs in the UK.

Various drivers are thought to be behind this growth including changing diets, as more consumers seek meat-free alternatives, updated health information, a growing love for breakfast food and the popularity of baking television programs.

At the same time, egg consumption reached the highest it has been in seven years in the US, with demand for protein-rich foods soaring, says the American Egg Board.

Meanwhile, the egg industry in Asia also continues to experience rapid growth, with China dominating the region’s egg production, accounting for more than 60% of the Asian total, according to industry analyst Terry Evans.

The humble, multifunctional egg

Eggs are a highly desirable and nutritious food.

They can impart characteristic taste or texture to a food product, provide leavening to bakery products and retard crystallization in foods and candies.

Providing high quality eggs and egg products is crucial to the sustainable economic viability of the egg industry.

A review of surveys conducted in the EU indicated that shell strength, albumen consistency (including height) and yolk colour (intensity of yolk pigment) are the main measures of quality important to consumers.

As a result, guaranteeing quality is essential to meeting consumer expectations.

Determinants of quality

As soon as an egg is laid, changes in the contents start to occur and a steady decline in internal quality begins.

The egg also starts to lose weight.

The conditions of the albumen are primarily responsible for the internal quality assessment.

A good quality egg is expected to have a firm and round yolk surrounded by a thick albumen and distinctly thinner outer albumen when broken out.

During storage, the thick albumen slowly breaks down resulting in a thinner albumen.

This albumen quality is often measured as a function of the height of the inner thick albumen.

The Haugh unit is a measure of egg quality based on the height of its egg white (albumen).

The test was introduced by Raymond Haugh in 1937 and remains an important industry measure of egg quality next to others such as shell thickness and strength.

Haugh units are directly correlated to egg grading criteria.

Eggs with Haugh value of 72 or higher are considered to be of AA quality.

Egg quality testing

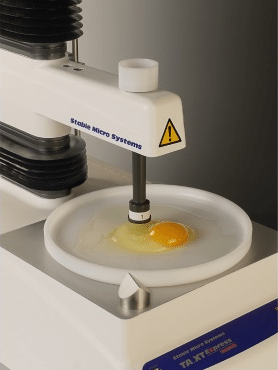

A suite of egg testing procedures from an instrument manufacturer enables egg producers and packers to measure accurately and consistently the quality of their products.

They can regularly monitor a range of parameters to ensure eggs meet the required quality standards and that these are maintained throughout the laying period.

It is important to assess the birds so that the eggs from the best flocks are sold to the customers that demand the highest quality.

On the other hand, flocks that consistently produce inferior eggs can be directed towards other products that do not require such high quality standards as whole eggs or maybe dealt with accordingly.

Tests now available include whole egg weight, shell breaking strength and deformation, egg albumen height, Haugh Unit calculation, shell thickness and vitelline membrane strength.

Egg producers can also manually input the colour of the yolk so it is digitally stored alongside all other testing data.

Measurement parameters & testing procedures

- Whole egg weight

Egg weight is genetically linked to all three of the major components: shell, albumen and yolk.

The link between egg weight and albumen weight is higher than that between egg weight and shell or yolk weight, and as egg size increases, so does the percentage of albumen.

By placing the egg in a cradle mounted to the calibration platform of the instrument, its weight can be measured and recorded in grams.

- Shell breaking strength

Shell strength, which refers to the ability of the shell to remain sound during transit from the hen to the consumer, is economically the most important of all the quality characteristics.

Shell structural quality is important because eggs that are structurally sound will arrive at the consumer in the best condition.

Poor shell quality will result in more cracked eggs, which mean losses for the producer.

The force required to crush a shell is a measure related to its integrity and resistance to breakage.

At the point of break, the force is recorded in grams and used as the shell breaking strength.

- Shell deformation

At the point of breaking, the compression distance is recorded.

This is the degree of deformation in mm that the shell can withstand before irreversible breakage.

- Egg albumen height

The greater the albumen height, the better the albumen quality.

Height can vary from as low as 1. in stale eggs of poor quality to 12 mm in good quality fresh eggs.

Generally the younger the bird producing newly laid eggs, the higher the albumen height.

- Haugh Unit

The Haugh Unit has been widely accepted throughout the world as the ‘gold standard’ for quantifying the internal quality and freshness of eggs.

It is the only objective measurement of ‘freshness’ and corresponds very closely to consumer preferences.

It is a ratio calculation involving the egg weight and thick albumen height.

The formula for calculating the Haugh unit is:

where:

- HU = Haugh unit

- h = height of the albumen in mm

- w = weight of egg in gm

A minimum Haugh unit measurement of 60 is desirable for whole eggs sold to the domestic consumer.

Most eggs leaving the farm should average between 75 and 85 Haugh units.

- Vitelline membrane strength (yolk quality)

With the increase in further processing of eggs, structural integrity of the vitelline (yolk) membrane has become an increasingly important issue for the egg-breaking industry.

Liquid products include whole egg, yolk or albumen.

The egg albumen is an excelllent foaming agent in baking and confectionery, but its effectiveness is dependent on the quality of albumen proteins.

Any crossover contamination with yolk can alter protein functionality and reduce foaming capacity.

Successful separation of the yolk from the albumen is extremely important, and the strength of the vitelline membrane, particularly its ability to withstand the breaking process, is critical.

The Vitelline membrane strength is measured by puncturing the yolk using a spherical probe.

The probe measures the force (in g) to rupture the yolk.

- Shell thickness

Shell thickness is almost entirely dependent on feed and the breed and age of the bird.

As the laying period progresses, egg shells become thinner.

The rate of decline in shell thickness is particularly marked in the latter half of the laying year but environmental temperature and nutritional factors also influence thickness.

A 0.25” spherical probe is used to approach a small section of the egg shell (broken from the shell of the egg tested with previous procedures) and measure the thickness of the shell (in mm) at the point of contact.

- Yolk colour

When judging the quality of an egg, another criteria that consumers apply for freshness is the egg yolk colour.

A simple but subjective method of determining this involves either the BASF Ovo-colour Fan or the DSM (formerly Roche) Yolk Colour Fan that expresses results in a one to 15 scale by means of visual comparison with calibrated cards in a fan of paper.

DSM has studied consumer preferences in many parts of the world and found that, while attitudes vary, consumers in most countries prefer an egg yolk colour with a DSM Yolk Color Fan value of 12 or more.

Outlook

In a highly competitive industry, achieving consistent quality is critical not only to customer and consumer satisfaction, but also to financial success.

Obtaining holistic information about the quality of eggs – shells as well as yolk and albumen – means producers can optimise their flocks, feeding regime and environmental conditions.

Detailed information obtained by texture analysis gives insight into the factors influencing quality, allowing adjustments to be made that will improve eggs’ resilience to storage, handling and transport, performance as a food ingredient and eating enjoyment.

All these contribute directly to the bottom line of all companies in the supply chain – which today no-one can afford to neglect.

Story by Jo Smewing, applications manager, Stable Micro Systems