A Technical University of Denmark (DTU) inventor and his partner have started their own business based on a microfluid chip that measures the flow properties of liquid products from paint to ketchup.

Fluidan, a small start-up that has just emerged from DTU is ready to launch an invention with the potential to revolutionize the market for measuring the flow properties and viscosity of liquids.

The invention is based on a new microfluid chip technology, which measures whether liquids such as yoghurt, creams, shampoo, and paint are flowing in the most appropriate way.

When production begins of the ‘micro-rheometer’, as it is known, it will be possible to install the device in the customer’s factory to measure liquids directly and continuously from the very pipes used in the production process.

This makes the invention unique.

At present, production specialists measure flow properties by running back and forth between factory and laboratory, alternately tapping fluids and carrying out measurements.

According to one of the founders, Anders L. Østergård—a chemical engineer and business manager with 25 years of experience of industrial markets and food ingredients—companies may be able to save up to DKK 1 million (US$0.15 million) a year by installing a unit.

“Today, it takes longer to perform quality assurance on liquid products than it does to produce them, because the measurement methods are extremely time-consuming,” says Østergård.

“Eliminating this traditional procedure would make it possible to double production.”

“We are therefore hoping to introduce a new mindset and make it ‘standard operating procedure’ to measure flow properties in the same way as temperature and pH value,” he says.

The invention can be used during production as well as in research and development for the benefit of food producers, companies operating in the chemical, color and paint industry, and refineries.

It should also benefit companies that make process equipment, as well as players in the oil industry.

Speeding up the process

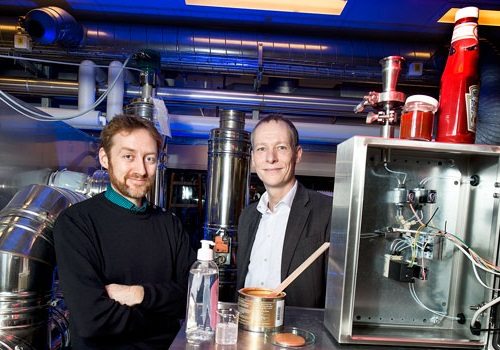

The inventor of the new measurement method is Fridolin Okkels, a graduate physicist who, until recently, held the position of associate professor at DTU Nanotech, where he worked with fluids and optimized structures.

He filed the first patent in 2011, and then in March 2014 he met Østergård through Copenhagen Spin-outs—an organization devoted to creating viable biotech and food technology companies based on public sector research.

Just before Christmas in 2014, the team concluded a licensing agreement with DTU and a financing agreement with an investor.

They officially opened the doors to their new business on 1 January this year.

“Today, it takes longer to perform quality assurance on liquid products than it does to produce them, because the measurement methods are extremely time-consuming,” says Østergård.

“The invention unites microfluidics with structure optimization—precisely the two areas that have fascinated me throughout my career.”

“I also noticed that even though manufacturing companies spend a lot of time measuring flow properties with a classic rheometer, they generally only use one or two critical values,” says Fridolin Okkels.

“So I thought that if I could measure the values in a run, I could speed up the process.”

How the rheometer works

When a fluid passes through a curved channel, it is affected by the channel walls, and this changes its flow.

This, in turn, results in a change in pressure.

The new invention is based on combining a simple tube with complex channel geometry and measuring the pressure drop in specific places.

The pressure signals are then subjected to mathematical processing, which provides the customer with precisely the values required to identify the correct flow properties.

Syddansk Teknologisk Innovation A/S is an investor in the start-up.

Global workplace

The start-up company has already proved that the technology works in the lab at DTU Food.

The next step is to test it in real life conditions to check whether it is sufficiently robust and can operate 24/7.

In the long term, it should be possible to develop a mobile device of around the size of a USB pen.

“The global market for equipment to measure flow properties is currently worth around DKK 1.5 billion,” says Østergård.

“Our target is to be generating an annual turnover of DKK 20-40 million four or five years from now.”

“The actual figure could be much higher in the long term, given that we have the whole world as our workplace.”

Story by Christina Tækker from DTU. This article was first published in DTUavisen no. 2, February 2015.