On July 29, 2014, the US Court of Appeals upheld the mandatory country-of-origin labeling (COOL) ruling for meat and meat products currently in place.

The decision denies a request for a preliminary injunction to block the implementation of the meat labeling rules.

Mettler Toledo has recently launched an on-demand online meat labeling webinar to help ensure retailers are compliant with regulations.

Entitled “Key Issues in Labeling and Packaging,” moderated by Erik Lieberman of FMI, discusses the laws and trends in nutrition labeling of single-ingredient meat and poultry, country of origin labeling, Bisphenol A regulations, enhanced meat product labeling, natural claims, facts-up-front front of pack labeling, extended producer responsibility and menu labeling.

Food News International finds out more from Patricia Johnson, Mettler Toledo North American Food Safety Expert about the impact of the ruling to food manufacturers globally.

FNI: What does the mandatory COOL ruling mean to manufacturers supplying to the US market?

Johnson: The COOL regulation, which went into effect in 2013, requires labels for cuts of meat to show where an animal is born, raised and slaughtered.

Meat packages now have these labels, indicating, for example, that the animals were, “Born, Raised and Slaughtered in the US” or “Born and Raised in Canada, Slaughtered in the US”.

The latest ruling on Tuesday, July 29, 2014 by the US Court of Appeals for the District of Columbia upheld the COOL ruling currently in place.

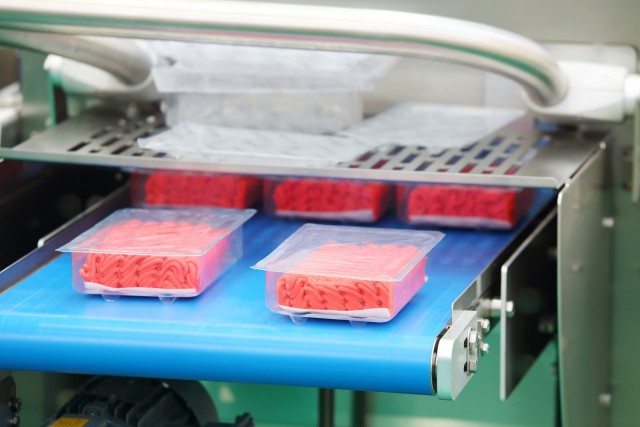

Manufacturers – which includes grocery retailers, as the meat backroom is considered a small manufacturing facility – need labels designed to display the necessary country-of-origin labeling, while faced with the challenge of displaying as much food product as possible.

Since clear visibility of the meat products is so important in the sale of meat, more information on the label can mean that more of the product is hidden from the line of sight.

FNI: What should they do to comply with this ruling?

Johnson: For this regulation, we recommend that retailer meat backroom manufacturers do not change the price look-up (PLU) record assignments and create new COOL records, but rather overwrite the existing COOL records with the new text.

FNI: What challenges do you foresee manufacturers would face while complying with the ruling?

Johnson: The challenges are related to the dynamic supply chain and sourcing of meat products.

Meat suppliers must accurately document the history of primals and the grocers must be able to ensure their PLU records have current information for born, raised and harvested in the text of their labels.

As the meat is cut and packaged in the backroom, the challenge operationally is to ensure each packaged cut has the correct information.

This requires item records by supplier (GTIN) to be downloaded to the scale or labeler, or, more commonly, the meat room employee must manually change the information in the scale/wrapping equipment for each packaging run.

The use of the standard PLU for one meat product becomes more difficult to accurately label the product when the same meat product is sourced from different vendors and farms.

FNI: How can they overcome these challenges?

Johnson: The difficulty for retailers is probably not that of adding the new language to the COOL records, but in organizing the data properly so that those new records can be easily assigned/reconfigured to the individual PLUs and then verifying that the resulting labels appear as desired and not an unexpected format.

Current scale software can be reconfigured easily to include any production step wording or country name as needed.

This is basically as simple as changing an ingredient in a product list.

The greater challenge for retailers would probably be maintaining the one forward-one back traceability records when products hit their receiving dock.

Retailers need to maintain data from multiple suppliers and not in a consistent format.

This becomes an even greater challenge if you change suppliers frequently.

For example, shrimp that may come from suppliers at different times of the year presents another level of difficulty.

Using an organized, best practices process to do this work is where professional service offerings can be helpful to customize a solution or improve a tedious and time-consuming process.

FNI: How will this ruling impact the larger food industries located in Asia and Europe?

Johnson: Meat manufacturers must ensure the information about their products gets to the North American grocers.

European suppliers and manufacturers already follow stricter and more uniform traceability regulations for the European Union market, so this will not be a major change for them.

For Asian suppliers, they will have to ensure accurate record keeping so that they can provide accurate information to the US grocers who receive their products.

FNI: How will this ruling be a game changer in the global food industry?

Johnson: The upheld ruling is another step in the steady increasing of traceability requirements.

It forces the industry to review processes and procedures—and does so before there is a food safety event.

This regulation requires better recordkeeping and communication throughout the food manufacturing process—from farm to fork. Improving communication and recordkeeping in a global market can benefit everyone.