Polyethylene terephthalate (PET) preform technology specialist SIPA has added refurbishing and conversion services to its total PET preform mound offering.

The new services will enable companies to optimize production, either by refurbishing molds — replacing some components by new ones in order to improve preform quality — or, via mound conversion, replacing parts in order to produce a completely new (and quite often lighter) preform design.

The advantage of mound conversion over buying a brand new mound lies in the lower capital investment involved, says SIPA.

The existing mound shoe is reused, and return of investment is faster.

Close to customers

The company has also put in place dedicated teams of professionals in three dedicated service centers to support the growing demand for refurbishing and conversions.

The service centers are located in Italy (Vittorio Veneto), China (Hangzhou), and the USA (Atlanta), thereby being close to its customers, simply logistics and shorten turnaround time.

In addition, the company offers an extensive mound audit program supported by its experts in the field.

This helps companies assess the state of wear of mound components in their own plant; different options on refurbishing or converting the audited mound can then be proposed.

SIPA has expertise in injection molding and stretch-blow molding all under one roof, so creative and sound packaging development programs can be bundled together with mound conversion programs, enabling its customers to take full advantage of their mold conversion investment.

Developing and producing molds, hot-runners

SIPA unveiled its new mold refurbishing and conversion services at K2013, an international plastics and rubber exhibition in Dusseldforf, Germany in October, 2013.

The hot half of each SIPA mold requires maintenance only after five million cycles, and it is possible to maintain components such as piston, flange O-rings and pin valves without opening the whole mold.

On energy consumption, with better distribution flow and a higher water temperature (14-15 °C instead of 8 °C), water consumption is minimized and performance in terms of condensation reduction is improved.

The smooth, polished, rounded profiles on SIPA hot runners reduce stress on material, resulting in better preform quality and a reduced AA level.

Mould systems also exhibit enhanced cooling performance, resulting in high quality preforms, maximum productivity and reduced production costs.

Lightweight X-Mould

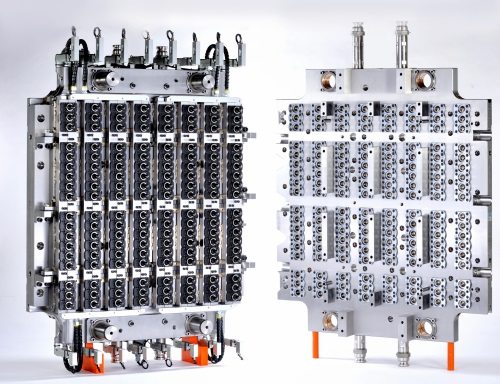

A 128-cavity preform mold incorporating SIPA’s innovative new X-Mould technology was another highlight on the company’s stand at K2013.

X-Mould enables processors to fill thin wall sections, so designers can create preforms that are longer or wider, for the creation of containers with more suitable stretch ratios.

It is now possible, for example, to design a 500ml bottle preform weighing 7.2 g that presents no production issues, either in injection or in stretch-blow, with existing legacy equipment.

Low weight, high performance

Even though the preforms are extremely light, the designs save on energy and material, enabling small carbon footprint along the production and supply chain.

SIPA says the X-Mould technology now makes it possible to produce preforms with ratios of length to wall thickness (L/t) close to 60, while applying injection pressure similar to that normally used for preforms with 45 L/t ratios.

This means that the stretch ratio in the final 7.2 g bottle is between 10.5 and 13.6, depending on its design—highly manageable for modern stretch-blow molding equipment.

In addition, the performance of the bottle, on the filling line and in use, meets all relevant requirements.

SIPA is making the X-Mould technology available across the market.

Injection molding of the new preform designs can be carried out, not only on the company’s latest generation of processing equipment—XFORM—but also on most existing preform injection molding machines, regardless of their brand.

Similarly, the preforms can be blown not only on SIPA linear and rotary stretch-blow lines, but also on lines from other suppliers.